Express Custom CNC Machining Services

Experience our online CNC machining service, offering rapid prototyping and batch production of parts in metals and plastics. Get instant quotes now and enjoy cost-effective custom CNC machining services.

- Custom CNC Prototyping - Create one-of-a-kind CNC prototypes tailored to your design.

- Mass Production Capabilities - Support for mass production runs exceeding 500,000 units.

- Precision Tolerances - Achieve precision with tolerances as tight as ±0.005 mm to meet your exacting standards.

- Swift Delivery - Enjoy the fastest delivery in just 3 business days.

Upload Your Design Files - Simply upload your designs and embark on the journey to production.

STEP STP SLDPRT IPT PRT SAT IGES IGS CATPART X_T OBJ STL files

- Your file security is our top priority; all uploads are strictly confidential.

Why Choose XLC for Custom CNC Machining Services?

XLC offers a comprehensive range of custom CNC machining services tailored for engineers, product developers, and designers. We specialize in rapid prototyping, small-batch machining, and high-volume production, ensuring that your needs are met with precision and efficiency. Here are the key reasons why XLC should be your manufacturing partner:

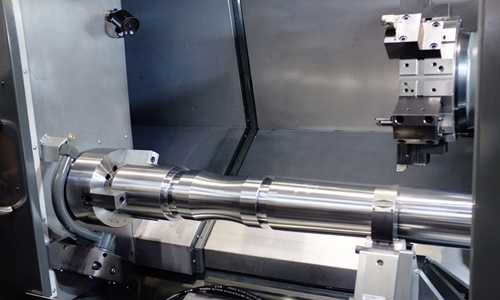

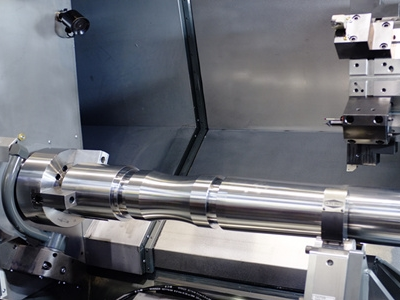

Advanced In-House Equipment: Our facilities are equipped with state-of-the-art HAAS CNC mills and lathes, Hexagon CMMs, and Olympus XRF analyzers. This advanced technology guarantees that your CNC parts are manufactured with the correct materials and precise dimensions.

Expertise in Precision Parts: Our experienced engineers have a deep understanding of CNC machining, having worked on numerous projects across various industries. They are adept at handling complex geometries and tight tolerances, ensuring that your precision mechanical parts and custom non-standard components meet the highest standards.

Quality Assurance: Every part undergoes rigorous inspection by our quality control department before shipment. This ensures that each CNC machined part is built to specification and free of defects, providing you with consistent high-quality results.

Fast Turnaround Times: Leveraging our in-house capabilities and a network of qualified manufacturing partners, XLC can deliver fast turnaround times. Whether you need a single prototype or a large-scale production run, we can meet your deadlines efficiently.

Customized Solutions: We understand the unique requirements of each project and provide customized solutions to meet your specific needs. Our flexible approach allows us to adapt quickly to your changing requirements, ensuring that your project is successful from start to finish.

By choosing XLC, you gain access to a reliable and efficient manufacturing partner that can deliver high-quality CNC machined parts with precision and speed.

CNC Machining Process Elaboration

CNC machining, or Computer Numerical Control machining, is a highly automated manufacturing process that utilizes computer-controlled tools to create precise and complex parts from various materials. This process has revolutionized the manufacturing industry due to its efficiency, precision, and versatility. Here is a detailed exploration of the CNC machining process, its applications, challenges, and future trends.

Basic Principles of CNC Machining

At its core, CNC machining involves the use of computer programs to control the movement of tools and workpieces. The process begins with a CAD (Computer-Aided Design) model, which is then converted into a CNC program using CAM (Computer-Aided Manufacturing) software. This program contains detailed instructions for the machine, specifying the tool paths, speeds, and other parameters required to shape the workpiece into the desired part.

The CNC machine, equipped with high-precision cutting tools, follows these instructions to remove material from the workpiece. Depending on the complexity of the part, CNC machines can have multiple axes, allowing for intricate movements and precise cuts. For instance, a 5-axis CNC machine can move the tool and workpiece in five different directions simultaneously, enabling the creation of complex three-dimensional shapes.

Applications of CNC Machining

CNC machining is widely used across various industries due to its ability to produce high-quality parts with tight tolerances and complex geometries. Here are some key applications:

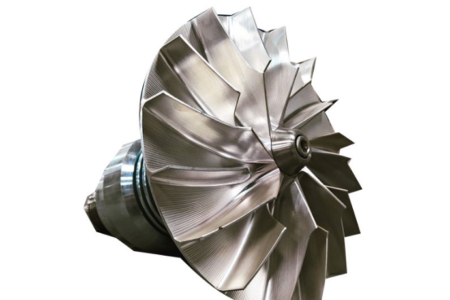

Aerospace: In the aerospace industry, CNC machining is crucial for producing components that require extreme precision and reliability, such as turbine blades, landing gear parts, and engine components. The ability to maintain strict tolerances ensures the safety and performance of these critical parts.

Automotive: The automotive sector relies heavily on CNC machining for the production of engine components, transmissions, and other parts. The high repeatability of CNC machining ensures that each part is identical, which is essential for maintaining the quality and performance of vehicles.

Electronics: In the electronics industry, CNC machining is used to create intricate components such as circuit boards and semiconductor parts. The precision of CNC machining allows for the miniaturization of electronic devices, enabling the development of smaller and more powerful gadgets.

Medical Equipment: CNC machining plays a vital role in the production of medical devices, including surgical instruments, implants, and diagnostic equipment. The high precision and consistency of CNC machining ensure that these devices meet the stringent quality and safety standards required in the medical field.

Challenges in CNC Machining

Despite its many advantages, CNC machining also faces several challenges:

High Initial Costs: The equipment and software required for CNC machining are expensive, which can be a barrier for small to medium-sized enterprises. However, leasing options and government subsidies can help mitigate these costs.

Skilled Labor Requirements: Operating CNC machines requires skilled technicians who understand both the hardware and software aspects of the system. The shortage of qualified personnel can lead to inefficiencies and increased labor costs.

Tool Wear and Maintenance: Tool wear is a common issue that affects the precision and efficiency of CNC machining. Regular maintenance and the use of high-quality tools are essential to extend tool life and maintain machining accuracy.

Complex Programming: Programming a CNC machine involves creating detailed instructions that must be error-free. This requires advanced software and skilled programmers to optimize the machining process and avoid costly mistakes.

Future Trends in CNC Machining

The CNC machining industry is continuously evolving, driven by technological advancements and changing market demands. Some notable trends include:

Automation and Integration: Increasingly, CNC machines are being integrated with other systems, such as CAD/CAM software and automated material handling systems, to create fully automated production lines. This integration enhances efficiency and reduces human error.

Advanced Materials and Processes: As new materials with unique properties are developed, CNC machining processes are being adapted to accommodate them. For example, the machining of exotic alloys and composites requires specialized tools and techniques to ensure optimal results.

Sustainability and Green Manufacturing: There is a growing focus on making CNC machining more sustainable by optimizing processes to reduce waste, energy consumption, and environmental impact. This includes the development of eco-friendly cutting fluids and the use of energy-efficient machines.

In conclusion, CNC machining is a versatile and essential manufacturing process that offers numerous benefits, including high precision, efficiency, and flexibility. Despite the challenges it faces, the continuous advancement of technology and the increasing demand for complex, high-quality parts ensure that CNC machining will remain a critical component of modern manufacturing for years to come.

Our CNC Machining Capabilities

We are always ready for the challenges of tight tolerances and complex CNC machined parts. Try out our precision CNC machining services and become our next satisfied customer.

CNC Milling Service

With 32 sets of 5-axis CNC milling machines in-house which allows us to mill tight tolerance plastic and metal parts with complex geometries easily. And we also offer low-cost machined parts by using our 3-, 4-axis milling machines.

CNC Milling Service

With 32 sets of 5-axis CNC milling machines in-house which allows us to mill tight tolerance plastic and metal parts with complex geometries easily. And we also offer low-cost machined parts by using our 3-, 4-axis milling machines.

CNC Milling Service

With 32 sets of 5-axis CNC milling machines in-house which allows us to mill tight tolerance plastic and metal parts with complex geometries easily. And we also offer low-cost machined parts by using our 3-, 4-axis milling machines.

CNC Milling Service

With 32 sets of 5-axis CNC milling machines in-house which allows us to mill tight tolerance plastic and metal parts with complex geometries easily. And we also offer low-cost machined parts by using our 3-, 4-axis milling machines.

CNC Milling Service

With 32 sets of 5-axis CNC milling machines in-house which allows us to mill tight tolerance plastic and metal parts with complex geometries easily. And we also offer low-cost machined parts by using our 3-, 4-axis milling machines.

CNC Milling Service

With 32 sets of 5-axis CNC milling machines in-house which allows us to mill tight tolerance plastic and metal parts with complex geometries easily. And we also offer low-cost machined parts by using our 3-, 4-axis milling machines.

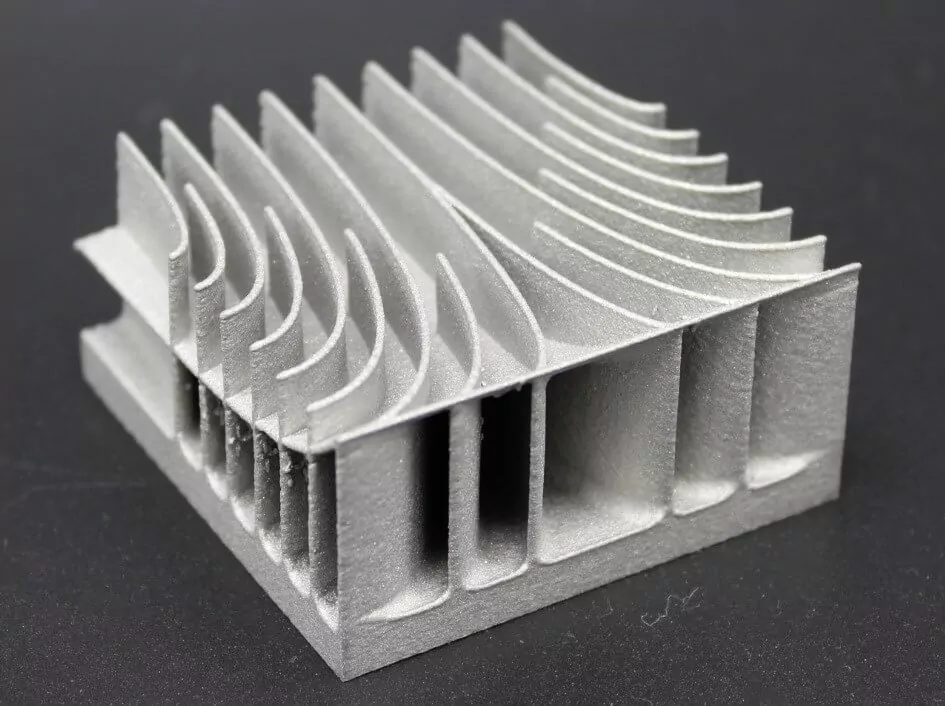

CNC Machining Excellence in Action

Explore our gallery of expertly crafted CNC machined parts, a testament to our precision and innovation. With XLC, we cater to a wide array of CNC machining needs, ensuring your project's success.

Precision in CNC Machining: Tolerance Standards, Material Options, and Surface Polishing

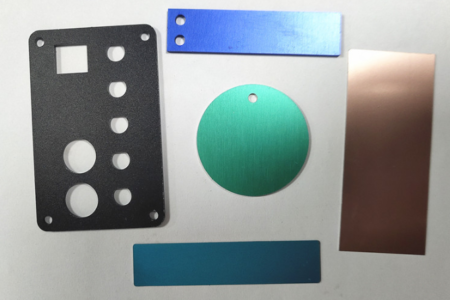

Surface Oxidation Process

Surface oxidation is a chemical treatment that enhances the durability and appearance of metal parts. It involves the creation of a thin oxide layer on the metal's surface, which provides corrosion resistance, increased hardness, and can also be used for decorative purposes. This process is commonly used in industries where metal components are exposed to harsh environments or require a specific aesthetic finish.

Mechanical Tolerances

Mechanical tolerances are the allowable variations in dimensions of a manufactured part. They ensure that components fit together correctly and function as intended within a machine or assembly. Tolerances account for factors like material expansion, wear, and manufacturing processes, and are critical for maintaining precision and quality in engineering designs.

The Choice of Raw Materials: A Key to Workpiece Success

Selecting the right raw materials is pivotal for workpiece durability, functionality, cost-efficiency, and aesthetics, as it directly impacts the machining process and the final product's quality.

Put your parts

into production today

All information and uploads are secure and confidential.

CNC Machining

FAQs

Yes. Upon receipt of your RFQ, our engineers will immediately review the CAD files and offer design feedback and optimization suggestions for CNC machining if required. This will help ensure improved quality of the CNC machined parts and identify key factors affecting CNC machining costs that influence the unit price."

XLC operates two dedicated CNC machining workshops, equipped with over 60 advanced CNC milling machines and lathes. With a team of 40+ skilled technical experts, we ensure in-house production capacity for up to 5,000 precision CNC machined parts across various specifications. Additionally, through our network of certified manufacturing partners, we can seamlessly scale to meet unlimited demand for additional CNC machining requirements.

XLC is one of China's top CNC machining companies for quality, speed, and customer service. Equipped with high-precision CNC machines, we consistently achieve tolerances of ±0.02 mm, with capabilities reaching ±0.01 mm or tighter when required. Please note that tighter tolerances may impact overall project costs.

Our production engineers meticulously review every RFQ received from customers to ensure accurate calculation of material and CNC machining costs. Most online CNC machining quotation systems on manufacturing platforms still lack sufficient precision. [Learn more through our case studies].

Based on our previous CNC machining orders, over 90% are completed within 7 days. Simple CNC machined parts can be delivered in as little as 2 days, while complex or large-scale components may require 15+ days. Production volume is another crucial factor to consider. Through our global CNC machining network, we can also manufacture your parts at workshops located closer to your US or European operations, significantly reducing lead times for delivery.

Advantages and Challenges of CNC Machining

In the CNC machining process, simple parts are more economical than complex ones. Although geometric complexity is possible, it requires additional steps that increase operational costs, such as multi-axis machining or multiple setups. The design complexity is limited by tool access: the angle and size of the cutting tool determine which areas of the workpiece it can and cannot reach. The startup costs of CNC machining can also be high. While it is a tool-less process, making its startup costs lower than molding and casting, machining requires slow setup and tool loading procedures that can only be executed by experienced machinists. If each setup only processes one or a few parts, it greatly increases the cost per part. Another challenge of CNC machining is material waste. Since machining is a subtractive process, a considerable portion of the workpiece becomes chips (waste) and is discarded after processing. However, the cost of the raw material (the stock used for machining) is much lower compared to some other forms of material (such as additive manufacturing powders).

CNC Machining for Various Industrial Applications

Our CNC machining service have been qualified by worldwide customers from different industries. We have been offering CNC machined parts for various industries which include the below list and more.

Automotive

CNC machining is vital to the industry, ensuring the accuracy of critical components, which is essential for safety and efficiency.

Shipbuilding

CNC machining is vital to the industry, ensuring the accuracy of critical components, which is essential for safety and efficiency.

Aerospace

CNC machining is vital to the industry, ensuring the accuracy of critical components, which is essential for safety and efficiency.

New Energy

CNC machining is vital to the industry, ensuring the accuracy of critical components, which is essential for safety and efficiency.

Drilling Rig

CNC machining is vital to the industry, ensuring the accuracy of critical components, which is essential for safety and efficiency.

Equipment

CNC machining is vital to the industry, ensuring the accuracy of critical components, which is essential for safety and efficiency.

Medical

CNC machining is vital to the industry, ensuring the accuracy of critical components, which is essential for safety and efficiency.

Aircraft

CNC machining is vital to the industry, ensuring the accuracy of critical components, which is essential for safety and efficiency.