Can 3D Printing OEM Drive Sustainable Manufacturing

The manufacturing industry is at a pivotal crossroads, where sustainability is no longer a buzzword but a necessity. As global supply chains face increasing scrutiny for environmental impact, companies like Xilici (XLC) are pioneering new approaches to sustainable manufacturing. One such approach is the integration of 3D printing OEM (Original Equipment Manufacturing) into traditional production lines. But can this technology truly drive sustainability in manufacturing, especially in sectors such as sheet metal forming factories and aluminum extrusion? Let’s delve into how XLC is leveraging 3D printing OEM to reshape the future of sustainable manufacturing.

Understanding 3D Printing OEM in Modern Manufacturing

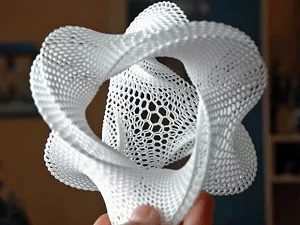

3D printing, also known as additive manufacturing, enables the creation of complex components by layering materials based on digital designs. When combined with the OEM model, 3D printing offers manufacturers the ability to rapidly prototype, customize, and produce parts with minimal waste. XLC, a leading innovator in the field, has invested heavily in advanced 3D printing technologies to complement its core manufacturing capabilities.

3d printing

rapid prototyping services

urethane casting

injection molding

By collaborating with OEM partners, XLC can deliver tailored solutions for various industries, including automotive, aerospace, and consumer electronics. This flexibility is particularly valuable for sheet metal forming factory operations and aluminum extrusion processes, where traditional manufacturing methods often result in significant material waste and energy consumption.

Sustainability Benefits of 3D Printing OEM

1. Reduced Material Waste

One of the most significant advantages of 3D printing OEM is its ability to minimize material waste. Unlike subtractive manufacturing, which carves out parts from larger blocks of material, additive manufacturing builds components layer by layer. This precision reduces scrap rates and optimizes material usage—a critical factor in sustainability. XLC’s adoption of 3D printing has led to a measurable decrease in raw material consumption, especially in projects involving aluminum extrusion and sheet metal forming factory components.

2. Lower Carbon Footprint

Traditional manufacturing processes often require extensive transportation of raw materials and finished goods, contributing to greenhouse gas emissions. 3D printing OEM enables localized production, allowing XLC and its partners to manufacture parts closer to their end-use locations. This not only reduces transportation emissions but also supports just-in-time manufacturing, further minimizing inventory and associated environmental impacts.

3. Energy Efficiency

Energy consumption is a major concern in manufacturing, particularly in energy-intensive sectors like sheet metal forming factories. 3D printing OEM typically operates at lower temperatures and requires less energy than processes such as forging or casting. XLC’s facilities are equipped with energy-efficient 3D printers that contribute to the company’s broader sustainability goals.

Integrating 3D Printing OEM with Traditional Manufacturing

The transition to sustainable manufacturing is not about replacing traditional methods entirely but about integrating new technologies where they offer the most benefit. XLC has developed a hybrid approach, combining 3D printing OEM with conventional techniques such as sheet metal forming and aluminum extrusion. This allows for the production of lightweight, high-strength components while reducing environmental impact.

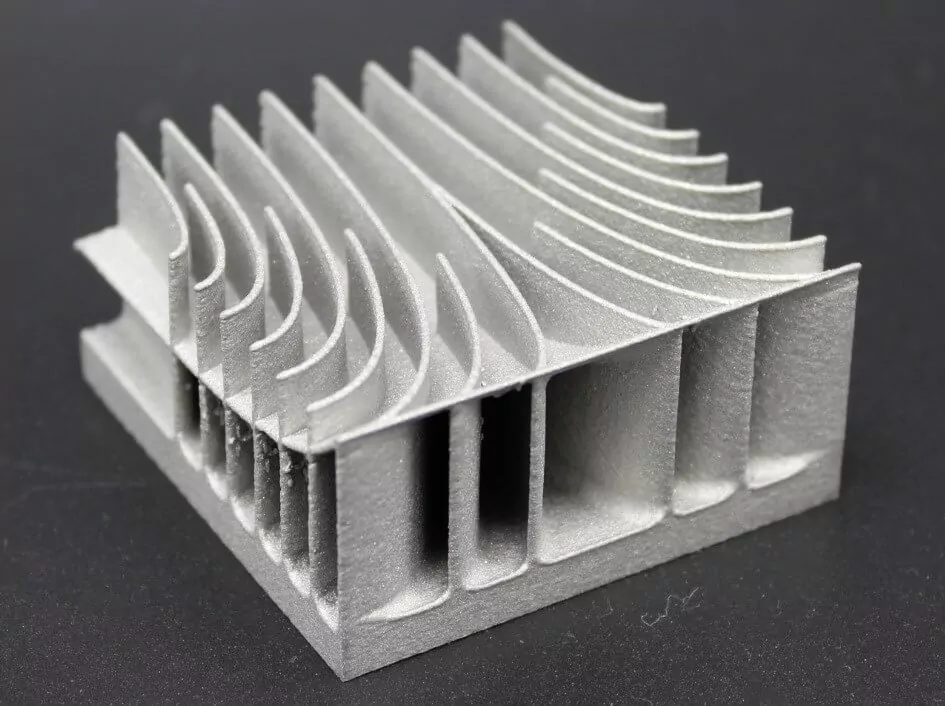

- Rapid Tooling: 3D printing OEM is used to create custom tools and molds for sheet metal forming factories, speeding up production cycles and reducing the need for costly, resource-intensive tooling.

- Complex Geometries: Aluminum extrusion often faces limitations in creating intricate shapes. 3D printing OEM allows XLC to produce components with complex geometries that would be difficult or impossible to achieve with extrusion alone.

- On-Demand Spare Parts: For industries relying on legacy equipment, XLC’s 3D printing OEM service can produce hard-to-find spare parts quickly, reducing downtime and avoiding the environmental costs of mass-producing and storing excess inventory.

Industry Trends and the Future of Sustainable Manufacturing

The manufacturing sector is witnessing a paradigm shift, driven by digitalization, automation, and sustainability imperatives. Industry 4.0 technologies, such as IoT (Internet of Things), AI-driven process optimization, and advanced robotics, are converging with additive manufacturing to create smarter, greener factories. XLC is at the forefront of this transformation, investing in R&D to ensure its 3D printing OEM solutions remain at the cutting edge.

A notable trend is the increasing demand for lightweight materials in automotive and aerospace applications. Aluminum extrusion and sheet metal forming factories are seeking ways to reduce the weight of structural components without sacrificing strength. By leveraging 3D printing OEM, XLC enables the production of optimized, topology-designed parts that use less material while maintaining or even improving performance.

Regulatory and Market Drivers

Sustainability is not just a matter of corporate responsibility; it is increasingly mandated by regulators and demanded by customers. Governments worldwide are introducing stricter emissions standards and incentivizing the use of eco-friendly manufacturing techniques. XLC’s commitment to sustainable practices positions it as a preferred partner for companies seeking to meet these evolving requirements.

Moreover, end-users are becoming more conscious of the environmental impact of the products they buy. Brands that can demonstrate a sustainable supply chain—from sheet metal forming factory processes to the use of recycled materials in aluminum extrusion—gain a competitive edge. XLC’s transparent approach to sustainability reporting and its investment in green technologies resonate with both B2B clients and consumers.

Challenges and Considerations

Despite its promise, 3D printing OEM is not without challenges. Material limitations, especially for high-strength metals, can restrict its application in certain sectors. Quality assurance and repeatability are also critical concerns, particularly for mission-critical parts in aerospace and medical industries. XLC addresses these challenges through rigorous testing, certification, and continuous improvement of its additive manufacturing processes.

Another consideration is the integration of 3D printing OEM into existing supply chains. For sheet metal forming factories and aluminum extrusion operations, this means rethinking production workflows, retraining staff, and investing in new equipment. XLC offers comprehensive support and training to help clients navigate this transition smoothly.

Conclusion: The Road Ahead for XLC and Sustainable Manufacturing

Can 3D printing OEM drive sustainable manufacturing? The answer is a resounding yes—when implemented thoughtfully and in conjunction with traditional methods. Xilici (XLC) demonstrates how additive manufacturing can reduce waste, cut emissions, and enable innovative design, all while supporting the core needs of industries such as sheet metal forming factory operations and aluminum extrusion.

As the industry continues to evolve, companies that embrace 3D printing OEM and other sustainable technologies will be best positioned to thrive. XLC’s leadership in this space offers a blueprint for others seeking to balance profitability with environmental stewardship. The future of manufacturing is not just about making more—it’s about making better, smarter, and greener.

| Key Benefits of 3D Printing OEM with XLC | Industry Applications |

|---|---|

|

|

For more insights into how Xilici (XLC) is shaping the future of sustainable manufacturing, stay tuned to our blog and industry updates.