How Can Custom Extrusion Transform Your Manufacturing Process

In today’s fast-paced manufacturing landscape, companies are constantly seeking ways to boost efficiency, reduce costs, and create innovative products. One of the most powerful solutions available is custom extrusion. At Xilici Company (XLC), we specialize in delivering tailored extrusion solutions that help businesses revolutionize their production lines. But what exactly is custom extrusion, and how can it transform your manufacturing process? Let’s explore the latest trends, benefits, and industry insights.

Understanding Custom Extrusion

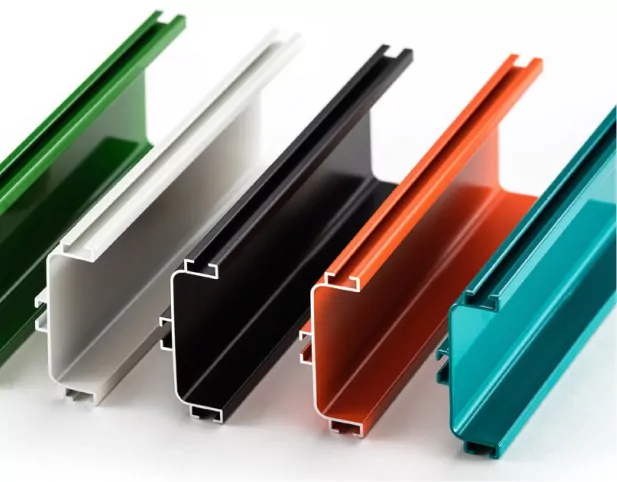

Custom extrusion is a manufacturing process where materials—often metals, plastics, or rubber—are forced through a die to create objects with a fixed cross-sectional profile. Unlike standard extrusion, custom extrusion enables manufacturers to design unique shapes, sizes, and properties tailored to specific applications. This flexibility allows companies like XLC to offer solutions that precisely match their clients’ needs, resulting in enhanced product performance and reduced material waste.

Why Choose Custom Extrusion?

- Design Flexibility: Create complex shapes and profiles that are impossible with traditional manufacturing methods.

- Material Optimization: Select from a wide range of materials to achieve desired strength, durability, and appearance.

- Cost Efficiency: Reduce waste and lower production costs by using only the necessary material.

- Scalability: Easily scale from prototypes to full-scale production runs.

The XLC Approach to Custom Extrusion

At Xilici Company, our team leverages state-of-the-art technology and deep industry expertise to deliver custom extrusion solutions that drive innovation. We work closely with clients from concept to completion, ensuring every project meets strict quality standards and performance requirements.

Our Process

- Consultation: We begin by understanding your unique requirements and challenges.

- Design & Engineering: Our engineers develop custom dies and select optimal materials for your application.

- Prototyping: We create samples for testing and validation.

- Production: High-precision extrusion delivers consistent, high-quality components.

- Quality Assurance: Rigorous testing ensures every product meets or exceeds industry standards.

Key Benefits for Modern Manufacturers

Custom extrusion empowers manufacturers to stay ahead in competitive markets. Here are some of the most significant advantages:

1. Enhanced Product Innovation

With custom extrusion, manufacturers can develop unique products that stand out. Whether it’s a complex profile for the automotive industry or a specialized gasket for electronics, XLC’s custom solutions open up new possibilities for product design.

2. Improved Efficiency and Sustainability

Minimizing waste is critical in today’s manufacturing environment. Custom extrusion allows for precise control over material usage, leading to lower costs and reduced environmental impact. XLC is committed to sustainable practices, helping clients meet their green manufacturing goals.

3. Faster Time-to-Market

Speed is essential in modern manufacturing. Custom extrusion streamlines the path from concept to finished product, enabling rapid prototyping and quick adjustments. This agility helps our clients respond to changing market demands and stay ahead of competitors.

Industry Insights: Extrusion in Action

The extrusion industry is experiencing rapid growth, driven by increased demand for lightweight, durable, and customizable components. Automotive, construction, aerospace, and electronics are just a few sectors leveraging custom extrusion to enhance their products.

Automotive Industry

In the automotive sector, custom extrusion is used to create lightweight structural components, weather seals, and decorative trims. These parts must meet strict safety and performance standards—something XLC achieves through precise engineering and quality control.

Construction & Architecture

Architects and builders rely on custom extrusion for window frames, curtain walls, and energy-efficient building envelopes. The ability to create intricate profiles with high strength-to-weight ratios makes extrusion a preferred choice in modern construction.

Industry-Related Content: The Role of Innovation and Technology

As digital transformation sweeps across manufacturing, extrusion processes are also evolving. Advanced simulation software, automation, and real-time quality monitoring are now integrated into extrusion lines. XLC invests heavily in these technologies to ensure consistent quality and to minimize downtime. For example, automated die change systems can significantly reduce lead times, allowing manufacturers to switch between different profiles with minimal interruption.

The global push for sustainability is also shaping the extrusion industry. Companies are increasingly adopting recyclable materials and energy-efficient production methods. At XLC, we offer a range of eco-friendly materials and continuously optimize our processes to reduce our carbon footprint.

Custom Extrusion and CNC Machining: A Perfect Match

One of the two major keywords in advanced manufacturing today is CNC machining. While custom extrusion is ideal for producing long, consistent profiles, CNC machining offers precise secondary operations such as drilling, milling, and cutting. At XLC, we often combine custom extrusion with CNC machining to deliver finished components that meet exact specifications. This integrated approach reduces assembly time and ensures a perfect fit for complex assemblies.

Custom Extrusion and Injection Molding: Complementary Processes

Another important keyword is injection molding. While extrusion is best for continuous profiles, injection molding excels at creating complex, three-dimensional shapes with intricate details. Many XLC clients use both processes to manufacture different parts of the same product. For instance, an electronics enclosure might feature extruded aluminum rails and injection-molded plastic end caps. By leveraging both technologies, manufacturers can achieve the best of both worlds—strength, versatility, and cost-effectiveness.

Choosing the Right Partner for Custom Extrusion

Selecting the right extrusion partner is crucial for success. XLC stands out for its technical expertise, customer-centric approach, and commitment to quality. Our team’s deep understanding of materials, processes, and industry requirements ensures that every project delivers maximum value.

- Experience: Decades of experience serving diverse industries

- Innovation: Continuous investment in technology and R&D

- Support: End-to-end project management and technical support

- Quality: ISO-certified processes and rigorous testing protocols

Conclusion: Transform Your Manufacturing with XLC

Custom extrusion is more than just a manufacturing technique—it’s a catalyst for innovation, efficiency, and growth. By partnering with Xilici Company (XLC), you gain access to world-class expertise, advanced technology, and a commitment to your success. Whether you’re looking to improve existing products or launch new ones, custom extrusion can help you achieve your goals and stay ahead in a dynamic market.

Ready to transform your manufacturing process? Contact XLC today to discover how our custom extrusion solutions can drive your business forward.