How Does Precision Machining Enhance Industrial Tool Durability

In the fast-paced world of industrial manufacturing, the longevity and reliability of tools are critical to maintaining productivity and reducing operational costs. One of the most significant advancements driving these outcomes is precision machining. At xilici (XLC), a leading innovator in machining solutions, the focus is on leveraging cutting-edge technologies to deliver tools that exceed industry standards for durability and performance. In this article, we’ll explore how precision machining enhances tool durability, delve into related industry trends, and touch on the importance of surface finishing and tight tolerances in achieving superior results.

The Role of Precision Machining in Modern Industry

Precision machining refers to the process of removing material from a workpiece while maintaining extremely tight tolerances. This approach ensures that each component is manufactured to exact specifications, minimizing errors and inconsistencies. For companies like XLC, precision machining is not just a process—it’s a philosophy that underpins every stage of tool production, from design to final inspection.

Industries such as aerospace, automotive, medical device manufacturing, and energy production rely heavily on precision-machined tools and components. In these sectors, even minor deviations in tool geometry can lead to catastrophic failures or reduced efficiency. By embracing precision machining, XLC ensures that its clients receive tools that meet or exceed the most stringent industry requirements.

Why Durability Matters in Industrial Tools

Durability is a key factor in the total cost of ownership for industrial tools. Frequent tool replacement not only increases direct costs but also leads to downtime, impacting overall productivity. Precision machining addresses this challenge by producing tools with consistent quality, enhanced wear resistance, and superior mechanical properties.

- Reduced Wear and Tear: Tools manufactured with precision machining exhibit smoother surfaces and fewer micro-defects, which translates to less friction and wear during operation.

- Improved Material Integrity: By maintaining tight tolerances, XLC ensures that stress concentrations are minimized, reducing the risk of premature tool failure.

- Enhanced Performance: Precision-machined tools maintain their cutting edges and functional surfaces longer, resulting in more consistent performance over time.

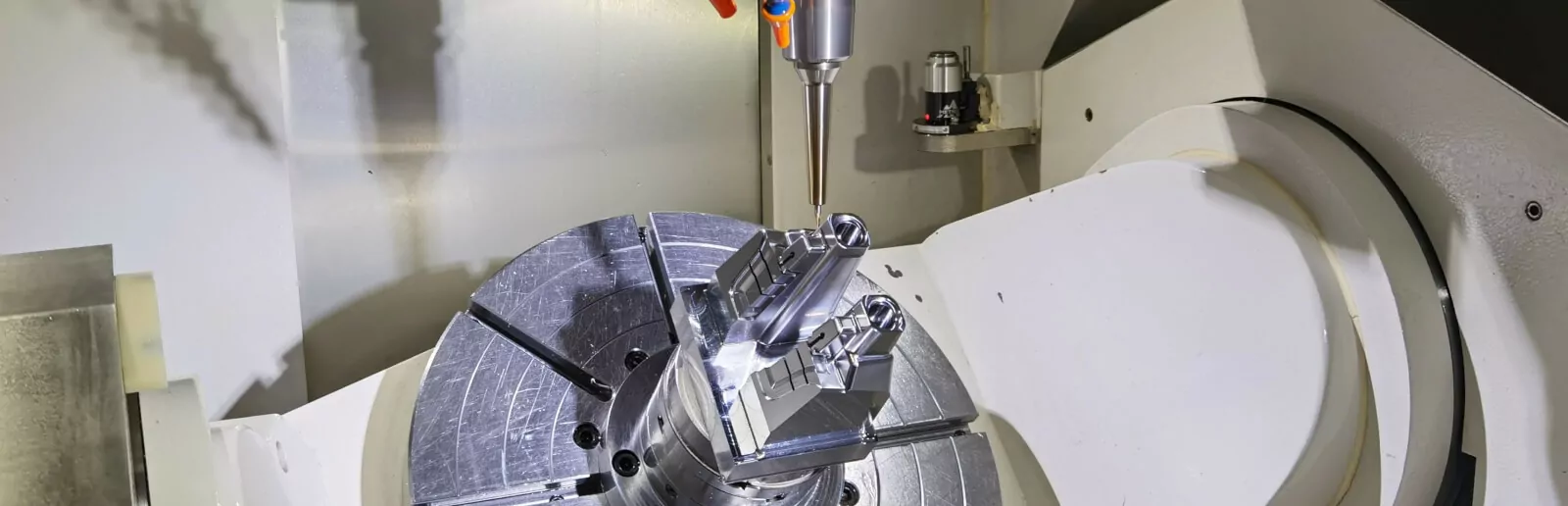

Key Technologies Driving Precision Machining at XLC

XLC invests heavily in state-of-the-art CNC (Computer Numerical Control) machines, advanced metrology equipment, and skilled personnel. This allows the company to achieve the high levels of accuracy required for today’s demanding applications. Some of the core technologies include:

- Multi-Axis CNC Machining: Enables complex geometries to be produced in a single setup, reducing errors and ensuring uniformity.

- Automated Quality Control: In-line inspection systems detect deviations in real-time, allowing for immediate correction and reducing scrap rates.

- Advanced Toolpath Optimization: Software-driven strategies minimize tool deflection and heat generation, which can compromise durability.

By integrating these technologies, XLC delivers tools that not only meet but often exceed client expectations for durability and precision.

The Importance of Surface Finishing

Surface finishing is a critical aspect of precision machining. A well-finished surface reduces friction, enhances corrosion resistance, and improves the overall lifespan of industrial tools. At XLC, various surface finishing techniques—such as grinding, polishing, and coating—are employed to achieve the desired properties.

For example, a high-quality surface finish can prevent the initiation and propagation of cracks, which are common failure points in tools subjected to cyclic loading. Additionally, surface finishing can improve the aesthetic appeal of tools, which is increasingly important in industries where branding and visual identity matter.

Meeting Tight Tolerances: The XLC Approach

Achieving tight tolerances is a hallmark of XLC’s manufacturing process. Tight tolerances refer to the allowable variation in a physical dimension, and maintaining these is essential for ensuring that tools fit and function as intended.

- Enhanced Interchangeability: Tools manufactured to tight tolerances can be easily replaced or interchanged without the need for adjustments, reducing downtime.

- Consistent Performance: Tight tolerances ensure that each tool performs identically, providing reliable results batch after batch.

- Improved Safety: In critical industries such as aerospace and medical devices, maintaining tight tolerances is essential for ensuring safety and compliance with regulatory standards.

XLC utilizes advanced measurement systems, including coordinate measuring machines (CMMs) and laser scanners, to verify that every tool meets the specified tolerances. This commitment to precision is a key factor in the company’s reputation for durable, reliable products.

Industry Trends: Automation and Sustainability

The industrial tooling sector is evolving rapidly, with automation and sustainability emerging as major trends. Automation, powered by robotics and AI, is enabling manufacturers like XLC to produce tools with greater consistency and at higher volumes. Automated systems can operate around the clock, further enhancing productivity and reducing lead times.

Sustainability is also becoming a focal point. Precision machining, when combined with advanced recycling and waste reduction strategies, can minimize the environmental impact of tool production. XLC is committed to adopting eco-friendly practices, such as using energy-efficient machinery and implementing closed-loop coolant systems, to support a greener manufacturing ecosystem.

Case Study: XLC’s Impact on the Automotive Sector

The automotive industry is a prime example of a sector that benefits immensely from precision machining. As vehicles become more complex and performance-driven, the demand for high-quality, durable tools has never been greater. XLC has partnered with leading automotive OEMs to supply precision-machined tools that are crucial for manufacturing engine components, transmission systems, and safety-critical assemblies.

By delivering tools that consistently meet tight tolerances and feature superior surface finishing, XLC helps automotive manufacturers achieve higher throughput, lower defect rates, and improved vehicle reliability. This partnership exemplifies the transformative impact of precision machining on industrial tool durability and, by extension, on end-product quality.

Challenges and Future Directions

Despite the many advantages, precision machining faces challenges such as rising material costs, the need for skilled labor, and the integration of new digital technologies. XLC is addressing these challenges through continuous investment in employee training, R&D, and digital transformation initiatives.

Looking ahead, the future of precision machining will likely be shaped by further advancements in automation, smart manufacturing, and the adoption of Industry 4.0 principles. XLC is well-positioned to lead this evolution, ensuring that its clients continue to benefit from the most durable and reliable industrial tools available.

Conclusion: The XLC Advantage in Tool Durability

Precision machining is the cornerstone of industrial tool durability. By focusing on advanced manufacturing processes, rigorous quality control, and continuous innovation, xilici (XLC) consistently delivers tools that stand the test of time. Whether through superior surface finishing, maintaining tight tolerances, or embracing industry trends like automation and sustainability, XLC remains a trusted partner for manufacturers seeking to enhance productivity and reduce costs.

For industries where tool durability is non-negotiable, partnering with a company like XLC is not just a choice—it’s a competitive advantage.