Custom Extrusion Innovations for Lightweight and Strong Components

In the fast-evolving world of manufacturing, the demand for lightweight yet robust components is skyrocketing. As industries such as automotive, aerospace, electronics, and renewable energy push boundaries, the need for innovative extrusion solutions has never been greater. Xilici Company (XLC) stands at the forefront of this revolution, pioneering custom extrusion innovations that deliver exceptional performance without compromising on strength or durability.

Understanding Custom Extrusion: The XLC Approach

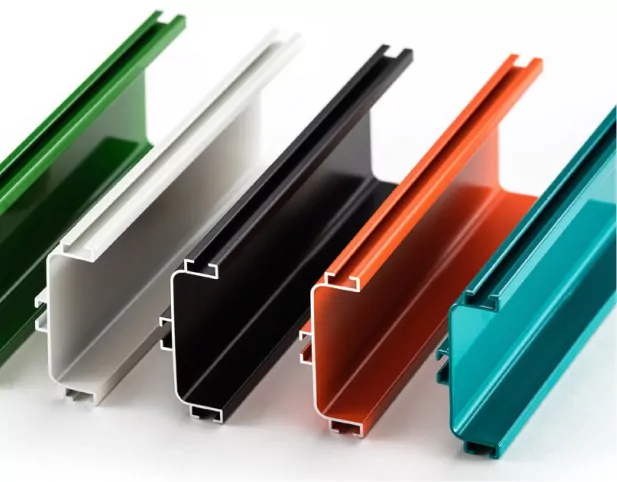

Custom extrusion is a specialized manufacturing process where materials—most commonly aluminum and advanced polymers—are forced through a die to create objects of a fixed cross-sectional profile. XLC leverages cutting-edge technology and engineering expertise to design and produce extrusions tailored to the unique requirements of each client.

Unlike standard, off-the-shelf extrusions, XLC’s custom solutions enable manufacturers to optimize weight, improve functionality, and enhance the aesthetics of their components. This flexibility is vital in industries where every gram counts and every millimeter matters.

Key Benefits of XLC’s Custom Extrusion Solutions

- Lightweight Structures: Advanced alloys and composite materials reduce weight while maintaining or improving strength.

- Enhanced Durability: Precision engineering ensures parts can withstand harsh environments and demanding operational cycles.

- Design Flexibility: Intricate profiles and complex geometries are achievable, supporting innovative product designs.

- Cost Efficiency: Material optimization and reduced waste lower production costs, especially at scale.

The Science Behind Lightweight and Strong Components

The drive towards lighter and stronger components is not just a trend—it’s a necessity. In automotive engineering, for instance, reducing vehicle weight directly correlates to improved fuel efficiency and lower emissions. In aerospace, every kilogram saved can translate into significant cost reductions and performance gains.

XLC’s R&D team continually explores new alloys, composites, and extrusion techniques to push the boundaries of what’s possible. By utilizing finite element analysis (FEA) and advanced simulation tools, XLC ensures that every custom extrusion meets rigorous strength-to-weight requirements, optimizing both performance and safety.

Industry Applications: Where XLC Makes a Difference

- Automotive: Lightweight frames, crash-resistant components, and energy-absorbing structures.

- Aerospace: High-strength fuselage parts, wing supports, and interior fittings.

- Electronics: Heat sinks, enclosures, and connectors with precise tolerances.

- Renewable Energy: Solar panel frames, wind turbine blades, and mounting systems.

Integrating CNC Milling for Precision and Quality

To complement its custom extrusion capabilities, Xilici Company has invested heavily in advanced machining technologies. One of the key processes is CNC milling—a computer-controlled manufacturing method that allows for the precise shaping and finishing of extruded components.

As a leading cnc milling factory, XLC offers end-to-end solutions, from extrusion to precision machining and final assembly. This integration ensures that every component not only meets dimensional specifications but also adheres to the highest standards of surface finish and structural integrity.

Why CNC Milling Matters

- Complex Geometries: CNC milling enables the creation of intricate features that are difficult or impossible to achieve through extrusion alone.

- Tight Tolerances: High-precision machining guarantees parts fit and function perfectly in their intended applications.

- Material Versatility: CNC milling accommodates a wide range of metals and plastics, expanding design possibilities.

With the growing reputation of cnc milling China as a global manufacturing hub, XLC partners with top-tier suppliers to ensure access to the latest equipment and best-in-class expertise. This global collaboration allows XLC to deliver competitive pricing without sacrificing quality or innovation.

Beyond Extrusion: XLC’s Commitment to Sustainability and Efficiency

Modern manufacturing isn’t just about performance—it’s about responsibility. Xilici Company is deeply committed to sustainable practices throughout its operations. By optimizing material usage, recycling scrap, and minimizing energy consumption, XLC reduces its environmental footprint while delivering top-tier products.

Additionally, XLC’s continuous improvement programs focus on lean manufacturing principles, ensuring that processes are efficient, waste is minimized, and lead times are shortened. This commitment to efficiency translates into faster project turnaround and greater value for customers.

Quality Assurance at Every Step

- Material Certification: All raw materials are sourced from reputable suppliers and certified for quality and compliance.

- In-Process Inspection: Automated and manual checks ensure every extrusion meets or exceeds client expectations.

- Final Testing: Mechanical, thermal, and environmental tests validate performance before shipment.

Industry Trends: The Future of Lightweight Manufacturing

The global shift towards electrification, automation, and digitalization is reshaping manufacturing landscapes. As electric vehicles, drones, and smart devices become ubiquitous, the demand for custom extrusions that combine lightness with strength will only intensify.

Emerging technologies such as additive manufacturing (3D printing), hybrid materials, and AI-driven design optimization are opening new frontiers. Xilici Company stays ahead of these trends by investing in research, upskilling its workforce, and fostering partnerships with universities and technology leaders.

Challenges and Opportunities

- Material Innovation: The development of new alloys and composites will unlock unprecedented possibilities for lightweight structures.

- Process Automation: Smart factories and digital twins will streamline production and boost quality control.

- Global Collaboration: Cross-border partnerships, especially with cnc milling China experts, will drive competitiveness and innovation.

For manufacturers seeking to stay ahead, partnering with a forward-thinking company like XLC provides access to the latest extrusion technologies, machining capabilities, and industry insights.

Conclusion: Why Choose Xilici Company (XLC) for Your Next Project?

In a world where performance, efficiency, and sustainability are paramount, Xilici Company (XLC) delivers unmatched value. With its expertise in custom extrusion, advanced CNC milling, and a relentless focus on innovation, XLC empowers manufacturers to create components that are lighter, stronger, and smarter.

Whether you’re developing the next generation of electric vehicles, aerospace systems, or high-tech consumer products, XLC offers the solutions, experience, and global reach you need to succeed. Discover how XLC’s extrusion innovations can transform your products—and your business.

Contact Xilici Company today to explore custom extrusion and CNC milling solutions tailored to your unique requirements.

Tags:mold making,metal casting,cnc turning,5 axis cnc machining