Achieve Superior Results with Mold Making Factory Technology

In today’s rapidly evolving manufacturing landscape, precise and efficient mold making is the foundation for high-quality product development. As industries demand faster turnaround, superior accuracy, and cost-effective solutions, the role of advanced mold making factory technology becomes paramount. xilici company (abbreviated as XLC) stands at the forefront of this revolution, delivering outstanding results through innovative processes and a commitment to excellence.

The Evolution of Mold Making: From Tradition to Technology

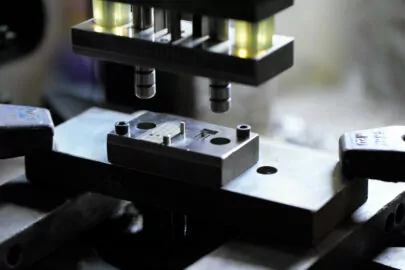

Mold making has a rich history rooted in craftsmanship and meticulous manual labor. However, with the advent of digital design, cnc machining, and automation, the industry has witnessed a paradigm shift. Today, companies like XLC harness cutting-edge technology to streamline every step of the mold making process—from concept to final production.

At XLC, the integration of advanced machinery, robust quality control systems, and skilled technicians ensures that every mold meets the highest standards of precision and durability. This technological evolution not only enhances productivity but also allows for greater customization and faster prototyping, essential for modern manufacturing demands.

Why Choose XLC for Mold Making?

- State-of-the-Art Facilities: XLC’s mold making factory is equipped with the latest CNC machines, 3D printers, and inspection tools, ensuring accuracy at every stage.

- Expert Team: The company’s engineers and technicians are highly trained, combining years of experience with a passion for innovation.

- Comprehensive Services: From design consultation to post-production support, XLC offers end-to-end solutions tailored to client needs.

- Quality Assurance: Rigorous testing and inspection guarantee that every mold delivers consistent, reliable performance.

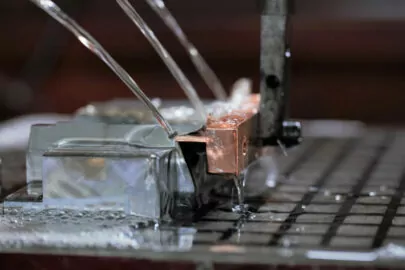

The Role of vacuum casting in Modern Mold Making

One of the most significant advancements in mold manufacturing is the adoption of vacuum casting. This technique, widely used in the XLC vacuum casting factory, allows for the rapid production of high-quality prototypes and small-batch parts. By eliminating air bubbles and minimizing material waste, vacuum casting ensures that the final products are both robust and dimensionally accurate.

Vacuum casting is particularly valuable for industries such as automotive, medical devices, and consumer electronics, where precision and material properties are critical. At XLC, the vacuum casting process is seamlessly integrated into the broader mold making workflow, providing clients with exceptional flexibility and speed.

Industry Insights: Trends Shaping Mold Making Factories

The mold making industry is experiencing a wave of transformation driven by several key trends:

- Digitalization: The use of CAD/CAM software, simulation tools, and digital twins enables manufacturers to optimize designs and predict performance before actual production.

- Automation: Automated machining and robotic handling reduce human error, increase throughput, and lower costs.

- Sustainable Manufacturing: Eco-friendly materials and energy-efficient processes are becoming standard, reflecting a broader commitment to environmental responsibility.

- Customization: With shorter product life cycles and diverse consumer demands, the ability to quickly adapt molds for new designs is more important than ever.

XLC remains at the cutting edge of these trends, continually investing in research and development to offer clients the most advanced solutions available. The company’s proactive approach ensures that customers benefit from the latest innovations, whether they require traditional injection molds or advanced vacuum casting services.

Case Study: Leveraging Vacuum Casting for Rapid Prototyping

A leading electronics manufacturer approached XLC with a challenge: develop a series of prototype components for a new product line within an extremely tight deadline. Traditional mold making methods would have required weeks, if not months. By utilizing the XLC vacuum casting factory, the team was able to deliver fully functional prototypes in just a few days.

The vacuum casting process provided several advantages:

- Accelerated turnaround time

- High-fidelity replication of intricate details

- Ability to test multiple material options

- Cost-effective production for limited quantities

This case highlights the transformative impact of integrating vacuum casting into the mold making workflow, enabling manufacturers to stay agile and responsive in a competitive market.

XLC’s Commitment to Quality and Innovation

At the heart of XLC’s success is an unwavering commitment to quality and continuous improvement. The company employs a comprehensive quality management system, with inspections at every stage of production. Advanced metrology equipment ensures that every mold meets or exceeds client specifications, while feedback loops drive ongoing refinements.

Innovation is also a core value at XLC. The company regularly collaborates with industry partners, universities, and research institutions to explore new materials, processes, and design methodologies. This collaborative spirit keeps XLC at the leading edge of mold making technology.

Benefits of Partnering with XLC

| Benefit | Description |

|---|---|

| Speed | Rapid prototyping and efficient production cycles reduce time-to-market. |

| Precision | Advanced equipment and skilled technicians deliver unmatched accuracy. |

| Flexibility | Custom solutions for projects of any size or complexity. |

| Cost-Effectiveness | Optimized processes minimize waste and maximize value. |

| Support | Comprehensive after-sales service and technical assistance. |

The Future of Mold Making: What’s Next?

Looking ahead, the mold making industry will continue to embrace digital transformation, with greater emphasis on automation, data analytics, and AI-driven optimization. Technologies such as additive manufacturing and smart factories are poised to further enhance efficiency and product quality.

For companies like XLC, staying ahead means not only adopting new tools but also cultivating a culture of innovation and learning. By fostering strong relationships with clients and partners, XLC ensures that its mold making factory remains a benchmark for excellence in the industry.

Conclusion: Achieve Superior Results with XLC

In a world where precision, speed, and reliability are non-negotiable, xilici company (XLC) offers the expertise and technology needed to achieve superior results. Whether you require traditional mold making, advanced vacuum casting, or a full-service vacuum casting factory, XLC delivers solutions that drive success. Partner with XLC and experience the future of mold making—today.