Anodizing Technology: The Revolutionary Approach to Aluminum Surface Treatment

Aluminum anodizing is a widely used electrochemical process that enhances the durability, corrosion resistance, and aesthetic appeal of aluminum parts. From aerospace components to everyday consumer electronics, anodized aluminum is everywhere. But how does it work, and why is it so important?

In this guide, we’ll explore:

✅ What aluminum anodizing is

✅ The step-by-step anodizing process

✅ Different types of anodizing

✅ Benefits & applications

✅ Common FAQs

1.What is Aluminum Anodizing?

Anodizing is an electrochemical process that thickens aluminum’s natural oxide layer, creating a hard, protective, and often decorative surface. Unlike paint or plating, anodizing chemically transforms the aluminum itself, making the coating more durable and long-lasting.

Key Characteristics of Anodized Aluminum:

✔ Corrosion-resistant – Withstands harsh environments

✔ Harder surface – More scratch-resistant than raw aluminum

✔ Decorative finishes – Available in various colors (black, gold, red, etc.)

✔ Non-conductive – The oxide layer acts as an electrical insulator

✔ Environmentally friendly – No harmful VOCs (unlike paint)

2.How Does Aluminum Anodizing Work?

The anodizing process involves submerging aluminum in an acid bath and passing an electric current through it. Here’s a detailed breakdown:

- Cleaning & Pre-Treatment

Before anodizing, the aluminum must be thoroughly cleaned to remove oils, dirt, and impurities.- This is done using:

- Alkaline cleaning – Removes grease and contaminants

- Etching – Creates a uniform matte finish by removing a thin layer of aluminum

- Desmutting – Removes any residual smut left after etching

- This is done using:

- Anodizing (Electrochemical Process)

The cleaned aluminum is immersed in an acid electrolyte (usually sulfuric acid) and connected to the positive terminal (anode) of a power supply. A cathode (usually lead or stainless steel) is placed in the tank.- When current flows:

- Oxygen ions from the acid react with aluminum atoms

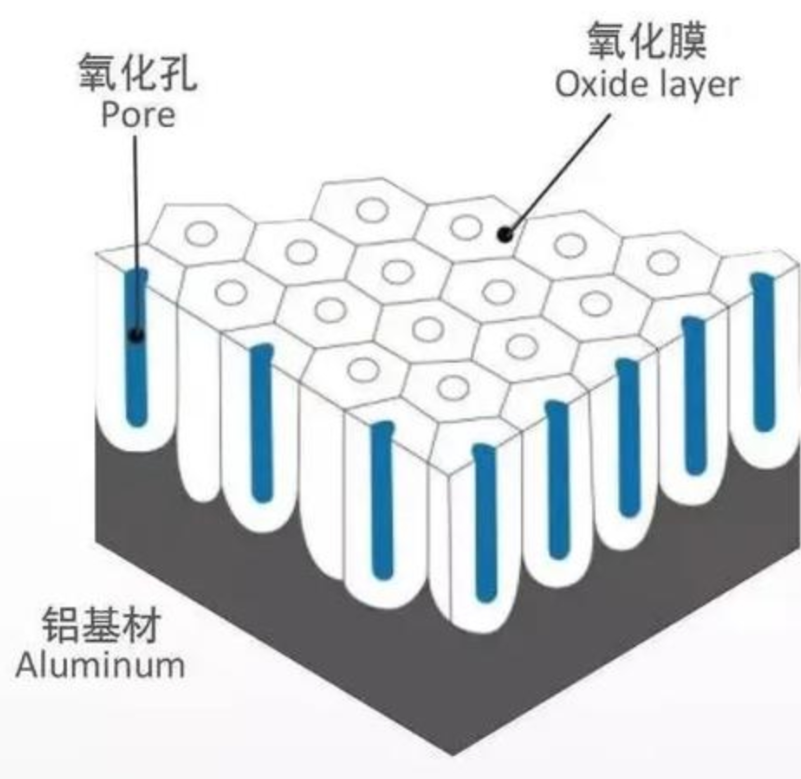

- A porous aluminum oxide (Al₂O₃) layer forms on the surface

- The thickness of this layer depends on voltage, time, and acid concentration

- When current flows:

- Coloring (Optional)

The porous oxide layer can absorb dyes for decorative finishes. Common coloring methods include:- Dip Dyeing – The part is soaked in organic/inorganic dyes (common for consumer products)

- Electrolytic Coloring – Uses metallic salts (e.g., tin or cobalt) for bronze/black shades (common in architecture)

- Interference Coloring – Produces iridescent effects via light refraction

- Sealing

The final step involves sealing the pores to lock in color and improve corrosion resistance.- Methods include:

- Hot Water Sealing – Boiling the part to hydrate and close the oxide layer

- Cold Sealing – Uses nickel or fluoride-based solutions for energy efficiency

- Mid-Temperature Sealing – A balance between hot and cold methods

- Methods include:

3.Types of Aluminum Anodizing

There are three main types, each with unique properties:

Type Thickness Key Features Common Uses

| Type I (Chromate Anodizing) | 0.5 – 8 µm | Uses chromic acid, good for tight tolerances | Aerospace, military |

| Type II (Sulfuric Acid Anodizing) | 5 – 25 µm | Most common, accepts dyes well | Consumer electronics, automotive |

| Type III (Hardcoat Anodizing) | 25 – 100 µm | Extremely durable, wear-resistant | Industrial machinery, firearms |

4.Benefits of Anodized Aluminum

✅ Longer Lifespan – Resists wear, UV fading, and corrosion

✅ Aesthetic Versatility – Available in many colors and finishes

✅ Eco-Friendly – No toxic coatings (unlike paint or plating)

✅ Better Adhesion – Paint and glue bond more effectively

✅ Electrical Insulation – Oxide layer is non-conductive

5.Applications of Anodized Aluminum

Anodized aluminum is used in industries where durability and aesthetics matter:

- Aerospace – Aircraft parts, satellites

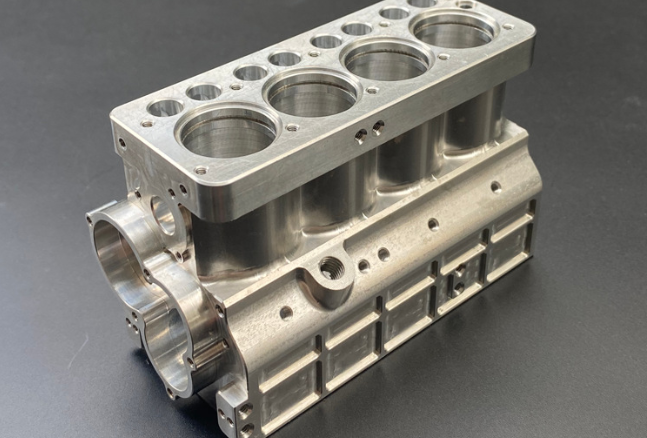

- Automotive – Trim, wheels, engine components

- Architecture – Window frames, façades

- Consumer Electronics – Smartphones, laptops

- Medical Devices – Surgical tools, implants

- Industrial Equipment – Pistons, hydraulic systems

6.FAQs About Aluminum Anodizing

- Does anodizing weaken aluminum?

No, it strengthens the surface while keeping the core metal intact. - Can anodized aluminum rust?

No, aluminum oxide is highly corrosion-resistant. - Is anodizing expensive?

It’s cost-effective compared to plating or powder coating. - Can you anodize at home?

Yes, but professional anodizing ensures better quality and safety.

Aluminum anodizing is a powerful process that enhances durability, aesthetics, and performance. Whether for industrial machinery or sleek consumer gadgets, anodized aluminum offers unmatched benefits.

Need anodizing services? Contact a professional metal finisher to get the best results for your project!