Boosting Innovation and Performance in 5 Axis CNC Machining

Introduction: The Evolution of 5 Axis CNC Machining

The manufacturing landscape has undergone a significant transformation in recent years, with advanced technologies reshaping the way components are designed and produced. Among these advancements, 5 axis cnc machining stands out as a game-changer, enabling unprecedented precision, flexibility, and efficiency. At the forefront of this revolution is Xilici Company (XLC), a global leader renowned for its commitment to innovation, quality, and customer-centric solutions.

What Sets 5 Axis CNC Machining Apart?

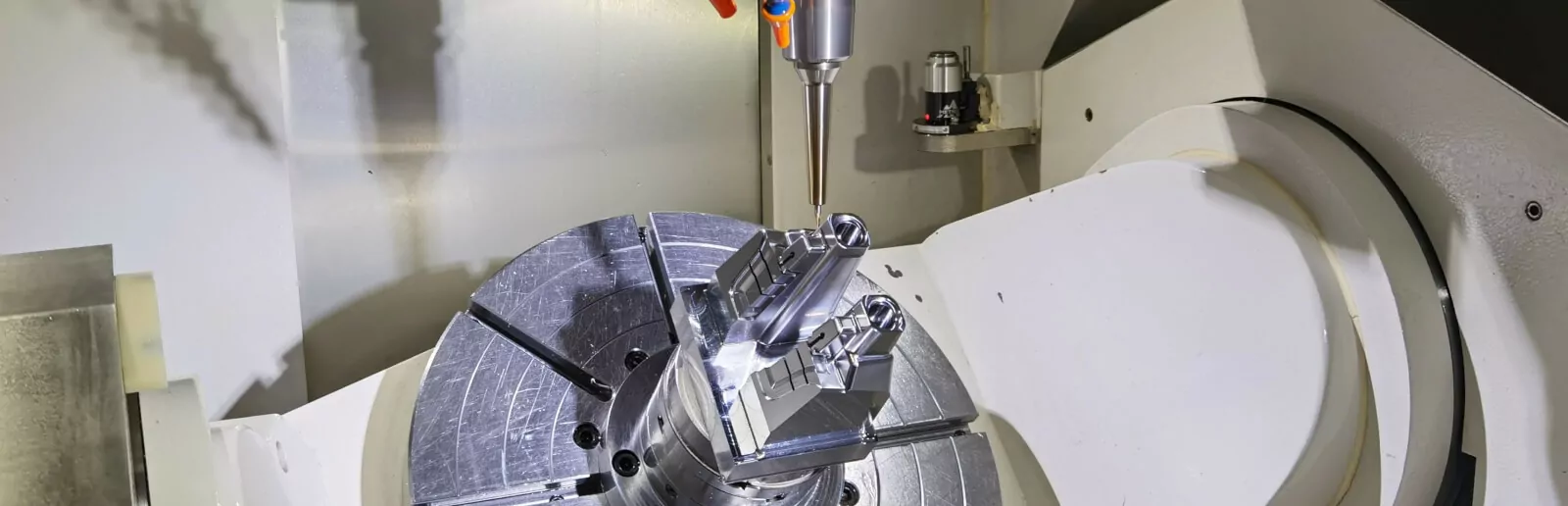

Traditional CNC machines operate on three axes—X, Y, and Z—limiting the ability to create complex geometries in a single setup. In contrast, 5 axis CNC machining introduces two additional rotational axes, allowing the cutting tool to approach the workpiece from virtually any direction. This breakthrough eliminates the need for multiple setups, reduces human error, and accelerates production cycles.

The versatility of 5 axis CNC machining is especially vital in industries such as aerospace, automotive, medical devices, and energy, where intricate parts and tight tolerances are non-negotiable. XLC has harnessed this technology to deliver solutions that not only meet but exceed industry standards.

Key Benefits of 5 Axis CNC Machining

- Enhanced Precision: Achieve complex contours and features in a single operation.

- Reduced Setup Time: Minimize manual intervention and increase throughput.

- Superior Surface Finish: Fewer repositionings mean smoother surfaces and less post-processing.

- Material Efficiency: Optimize material usage and reduce waste.

- Design Freedom: Manufacture complex geometries previously deemed impossible.

Xilici Company (XLC): Pioneering 5 Axis CNC Machining Solutions

Founded on a vision of technological excellence, Xilici Company (XLC) has established itself as a trusted partner for businesses seeking cutting-edge manufacturing solutions. With a state-of-the-art facility equipped with the latest 5 axis CNC machines, XLC offers a comprehensive suite of services—from rapid prototyping to high-volume production.

XLC’s team of experienced engineers and machinists brings together decades of expertise in CNC programming, process optimization, and quality assurance. Their collaborative approach ensures that each project is tailored to the client’s unique specifications, resulting in parts that perform flawlessly even in the most demanding applications.

Innovation at the Core of XLC

Innovation is more than a buzzword at XLC—it’s a way of life. The company invests heavily in research and development, staying ahead of emerging trends and integrating the latest advancements in 5 axis CNC machining. By leveraging smart manufacturing practices and digital twin technology, XLC simulates machining processes before they reach the shop floor, minimizing errors and maximizing efficiency.

Industry 4.0 Integration

XLC’s embrace of Industry 4.0 principles sets it apart from traditional machine shops. Through the use of IoT-enabled sensors, real-time data analytics, and automated quality control, XLC ensures that every component meets the highest standards of accuracy and consistency.

Driving Performance: XLC’s Commitment to Quality and Speed

In today’s competitive market, speed to market and product reliability are critical success factors. XLC addresses these challenges head-on by streamlining every stage of the manufacturing process. From digital design reviews to automated toolpath generation, the company eliminates bottlenecks and accelerates delivery times.

Quality is never compromised at XLC. The company adheres to rigorous inspection protocols, employing advanced metrology tools such as coordinate measuring machines (CMM) and laser scanners. This ensures that each part not only meets dimensional specifications but also performs reliably in its intended environment.

Case Study: Aerospace Component Manufacturing

One of XLC’s recent projects involved the production of complex turbine blades for a leading aerospace OEM. Utilizing their advanced 5 axis CNC machining capabilities, XLC was able to manufacture the blades with intricate cooling channels and tight tolerances—delivering parts that improved engine efficiency and reduced fuel consumption.

Expanding Horizons: Industry Trends and the Future of 5 Axis CNC Machining

The global demand for precision engineering continues to rise, driven by the proliferation of electric vehicles, renewable energy systems, and next-generation medical devices. As a result, the 5 axis CNC machining market is expected to witness robust growth over the next decade.

Innovative materials such as titanium alloys, carbon fiber composites, and advanced ceramics are becoming increasingly common in high-performance applications. These materials present unique machining challenges, requiring specialized tooling, coolant management, and process optimization. XLC remains at the forefront of addressing these challenges, offering expertise in both conventional and emerging materials.

Automation and Artificial Intelligence in CNC Machining

The integration of automation and artificial intelligence (AI) is revolutionizing the CNC machining industry. Automated pallet changers, robotic part loading, and AI-driven toolpath optimization are reducing labor costs and enhancing repeatability. XLC is actively exploring these technologies to further boost productivity and maintain its competitive edge.

Global Supply Chain Resilience

The recent disruptions in global supply chains have underscored the importance of agile manufacturing partners. XLC’s flexible production capabilities and commitment to on-time delivery make it a preferred supplier for companies seeking to mitigate risk and ensure business continuity.

Additional Industry Insights: The Role of CAD/CAM and Additive Manufacturing

Two keywords that are increasingly shaping the landscape of advanced manufacturing are CAD/CAM and additive manufacturing. CAD/CAM (Computer-Aided Design and Computer-Aided Manufacturing) software plays a pivotal role in 5 axis CNC machining by enabling seamless design-to-production workflows. XLC utilizes the latest CAD/CAM platforms to generate precise toolpaths and simulate machining operations, minimizing errors and reducing lead times.

Additive manufacturing, commonly known as 3d printing, is also influencing the future of CNC machining. While additive processes are ideal for rapid prototyping and complex geometries, CNC machining remains the gold standard for high-precision, high-strength components. XLC leverages both technologies, offering hybrid solutions that combine the best of both worlds.

Conclusion: Partner with XLC for Next-Level Performance

As the demands of modern manufacturing continue to evolve, partnering with an industry leader like Xilici Company (XLC) ensures access to the latest technologies, unparalleled expertise, and a relentless commitment to quality. Whether you require intricate aerospace components, high-performance automotive parts, or custom medical devices, XLC’s 5 axis CNC machining solutions deliver the innovation and performance needed to stay ahead of the competition.

To learn more about how XLC can help you achieve your manufacturing goals, contact their expert team today and experience the future of precision engineering.