CNC Machining High-precision aerospace component machining with ±0.002mm tolerance

Some information about CNC Machining High-precision aerospace component machining with ±0.002mm tolerance:

| Type | CNC Machining Services |

| Company Name | XLC |

| Micro Machining or Not | Micro Machining |

| Imported machines | 3-, 4-, and 5-axis |

| Place of Origin | Ningbo, China |

| Mass Production Capabilities | 500,000 units+ |

| Product Features | Flexibility,Repeatability,Automation,Excellent surface quality,Wide range of materials… |

| OEM and ODM | Yes |

| Precision Tolerances | ±0.005 mm |

| Application | Automotive,Industrial Machinery,Robotics & Automation,Electronics…etc |

| Payment | L/C,Cash,Western Union,T/T…etc |

| File formats | PRT,IPT,STL,STP,SLDPRT,SAT,STEP,IGES,OBJ… |

| Advanced In-House Equipment | HAAS CNC mills and lathes,Hexagon CMMs,Olympus XRF analyzers… |

| Materials | Aluminum,Brass,Copper,Titanium,Stainless Steel… |

| Packing | 89 * 26 * 93 According to container size, standard export package |

| Certificate | CE,ISO9001…. |

| 5-axis CNC milling machines | 32 sets |

| Color | silver gray,silver,gray, and customized color |

| Port | Ningbo/Shanghai… |

| Processing Type | CNC Turning,CNC Milling,CNC Machining,Grinding… |

| Trading Country | Mid east,South america,Europe,Southeast asia,Cambodia,Kuwait,Bolivia,Western Sahara… |

| Selling Units | Single item |

| Swift Delivery | Enjoy the fastest delivery in just 3 business days |

| After-sales Service | Online support |

Please note: The above table data is for reference only. For specific information, please contact us.

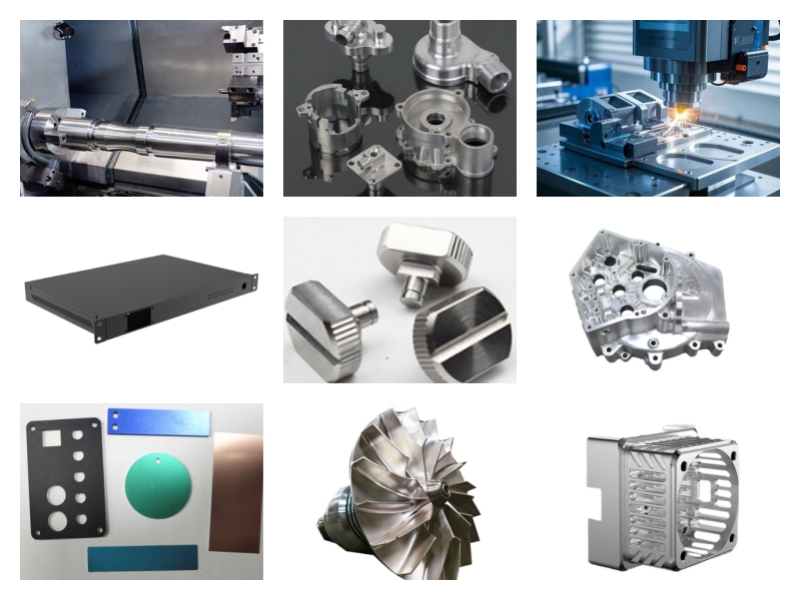

Our CNC Machining products

Our factory

Our workshops and production equipment for CNC Machining High-precision aerospace component machining with ±0.002mm tolerance

Our certificates and patents