Discover the Benefits of Rapid Tooling Factory for Mass Production

Introduction to Rapid Tooling Factories

Rapid tooling has revolutionized the manufacturing landscape, providing companies with the agility and speed necessary to stay ahead in today’s fiercely competitive markets. As an industry leader, Xilici Company (XLC) has harnessed the power of rapid tooling to deliver high-quality, cost-effective solutions for mass production. In this article, we’ll explore the core benefits of rapid tooling factories, delve into XLC’s unique approach, and discuss related technologies such as vacuum casting and the role of a modern vacuum casting factory.

What is Rapid Tooling?

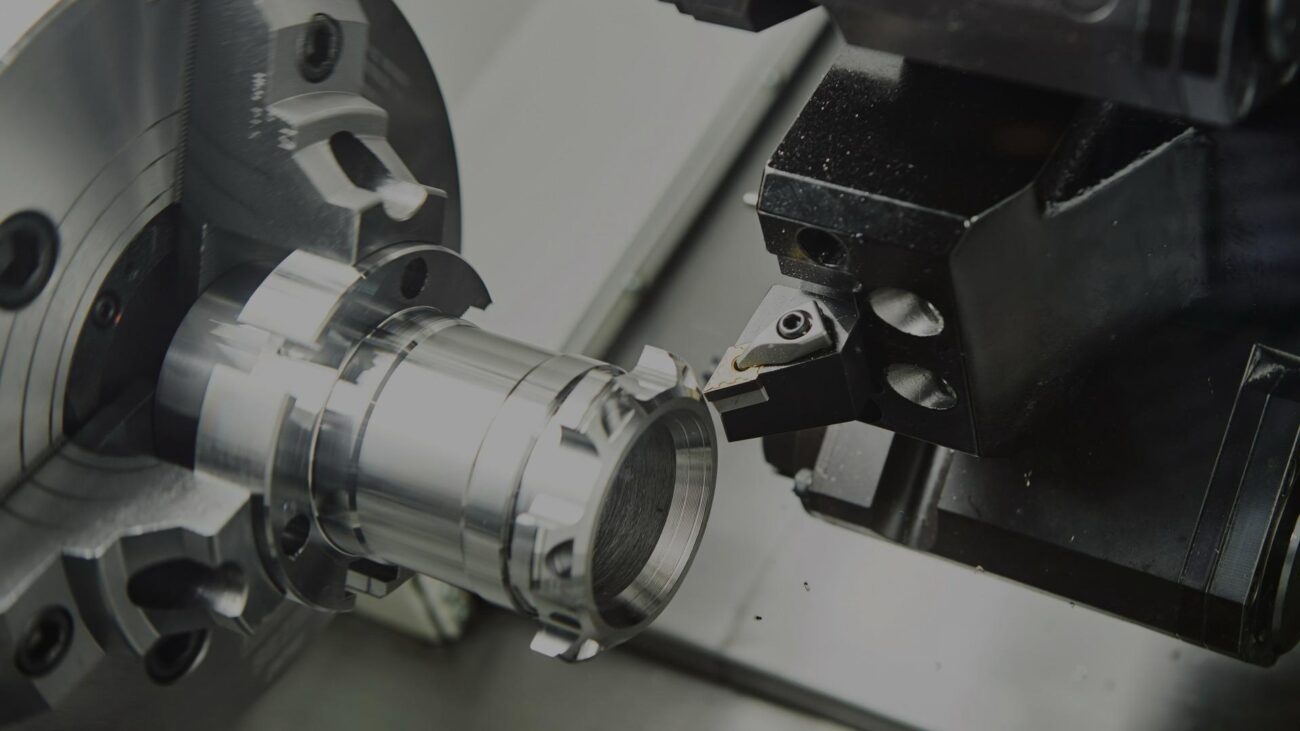

Rapid tooling refers to the process of creating production tools quickly and efficiently using advanced manufacturing technologies. Unlike traditional tooling methods, which can be time-consuming and costly, rapid tooling leverages digital design, additive manufacturing, and precision machining to drastically reduce lead times and costs. This methodology is especially crucial for companies like XLC, which serve industries requiring fast turnaround and high-volume output.

Types of Rapid Tooling

- Direct Rapid Tooling: Tools are produced directly from CAD data using additive manufacturing techniques.

- Indirect Rapid Tooling: Patterns or molds are first created, then used to produce the final tools through casting or molding processes.

The Xilici Company (XLC) Advantage

XLC has established itself as a trusted partner for businesses seeking rapid, reliable, and scalable manufacturing solutions. With a state-of-the-art rapid tooling factory, XLC integrates the latest technologies and skilled craftsmanship to meet the diverse needs of its clients. The company’s approach focuses on delivering not just speed, but also precision and flexibility—attributes highly prized in sectors such as automotive, aerospace, consumer electronics, and medical devices.

CNC Turning – WayKen Rapid

Key Benefits of Partnering with XLC

- Shorter Lead Times: XLC’s rapid tooling processes enable clients to move from design to production in a fraction of the time required by conventional methods.

- Cost Efficiency: By reducing the need for expensive, time-consuming tool fabrication, XLC helps clients optimize budgets and increase profitability.

- Design Flexibility: Rapid tooling allows for quick iterations and modifications, making it ideal for prototyping and mass production alike.

- Quality Assurance: Advanced quality control systems ensure that every component meets stringent industry standards.

- Scalable Solutions: Whether you need a small batch for prototyping or a large run for mass production, XLC’s rapid tooling factory can accommodate your requirements.

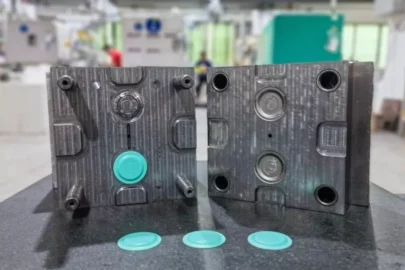

Integration of Vacuum Casting Technology

Vacuum casting is another essential service offered by XLC, enhancing the versatility of its rapid tooling factory. This process involves creating high-fidelity prototypes and parts using silicone molds and a vacuum environment. The result is detailed, accurate components suitable for testing, validation, and even end-use applications.

A modern vacuum casting factory like XLC’s is equipped to handle a wide range of materials and complex geometries. The synergy between rapid tooling and vacuum casting ensures that clients benefit from both speed and precision, whether they require a handful of prototypes or thousands of production parts.

Benefits of Vacuum Casting in Rapid Tooling Factories

- High-Quality Surface Finish: Vacuum casting delivers smooth, detailed surfaces that closely mimic final production parts.

- Material Versatility: A wide selection of polyurethane resins and elastomers can simulate various engineering plastics.

- Cost-Effective for Small Batches: Ideal for bridge production, pilot runs, or when traditional injection molding isn’t feasible.

Industry Applications and Trends

The demand for rapid tooling and related services is surging across multiple industries. In the automotive sector, for example, rapid tooling allows manufacturers to quickly adapt to changing consumer preferences and regulatory requirements. Aerospace companies leverage rapid tooling and vacuum casting to produce lightweight, high-strength components for prototypes and limited series production.

Consumer electronics benefit from rapid tooling by accelerating time-to-market for new gadgets, while the medical device industry relies on these technologies for fast, reliable production of complex devices and instruments. The rise of electric vehicles, IoT devices, and wearable technology continues to drive innovation in rapid tooling factory capabilities.

Emerging Trends in Rapid Tooling

- Digital Twin Integration: Using digital replicas of physical assets to optimize tool design and production processes.

- Automation and AI: Advanced robotics and artificial intelligence are streamlining workflows and improving consistency.

- Sustainable Manufacturing: Eco-friendly materials and energy-efficient processes are becoming standard in leading factories like XLC’s.

Choosing the Right Rapid Tooling Factory

Selecting the right partner is critical for maximizing the benefits of rapid tooling. XLC stands out due to its commitment to innovation, client collaboration, and continuous investment in technology. When evaluating a rapid tooling factory, consider factors such as technical expertise, range of services, quality control protocols, and the ability to scale production as your needs evolve.

Checklist for Selecting a Rapid Tooling Partner

| Criteria | Why It Matters |

|---|---|

| Technical Expertise | Ensures accurate, high-quality tooling and parts |

| Speed and Flexibility | Reduces time to market and allows for quick design changes |

| Comprehensive Services | Streamlines production by offering prototyping, vacuum casting, and mass production under one roof |

| Quality Assurance | Guarantees consistent, reliable output |

| Scalability | Supports growth from prototype to full-scale production |

Conclusion: The Future of Mass Production with XLC

As industries continue to evolve and demand faster, more flexible manufacturing solutions, rapid tooling factories are set to play an even greater role. With its advanced capabilities, integrated vacuum casting services, and client-centric approach, Xilici Company (XLC) is at the forefront of this transformation. By partnering with XLC, businesses can unlock new levels of efficiency, innovation, and competitiveness in mass production.

Whether you are launching a new product or scaling up for mass production, XLC’s rapid tooling factory and vacuum casting expertise provide the foundation for success in today’s dynamic marketplace.