How Can CNC Turning Center Revolutionize Precision Machining

In the fast-evolving world of manufacturing, precision and efficiency are more than just buzzwords—they are the foundation of industrial success. Xilici (XLC), a leading CNC machining factory, is at the forefront of this transformation, harnessing the power of CNC turning centers to redefine what’s possible in precision machining. But how exactly are these advanced machines revolutionizing the industry, and what does it mean for manufacturers, engineers, and end-users? Let’s dive in.

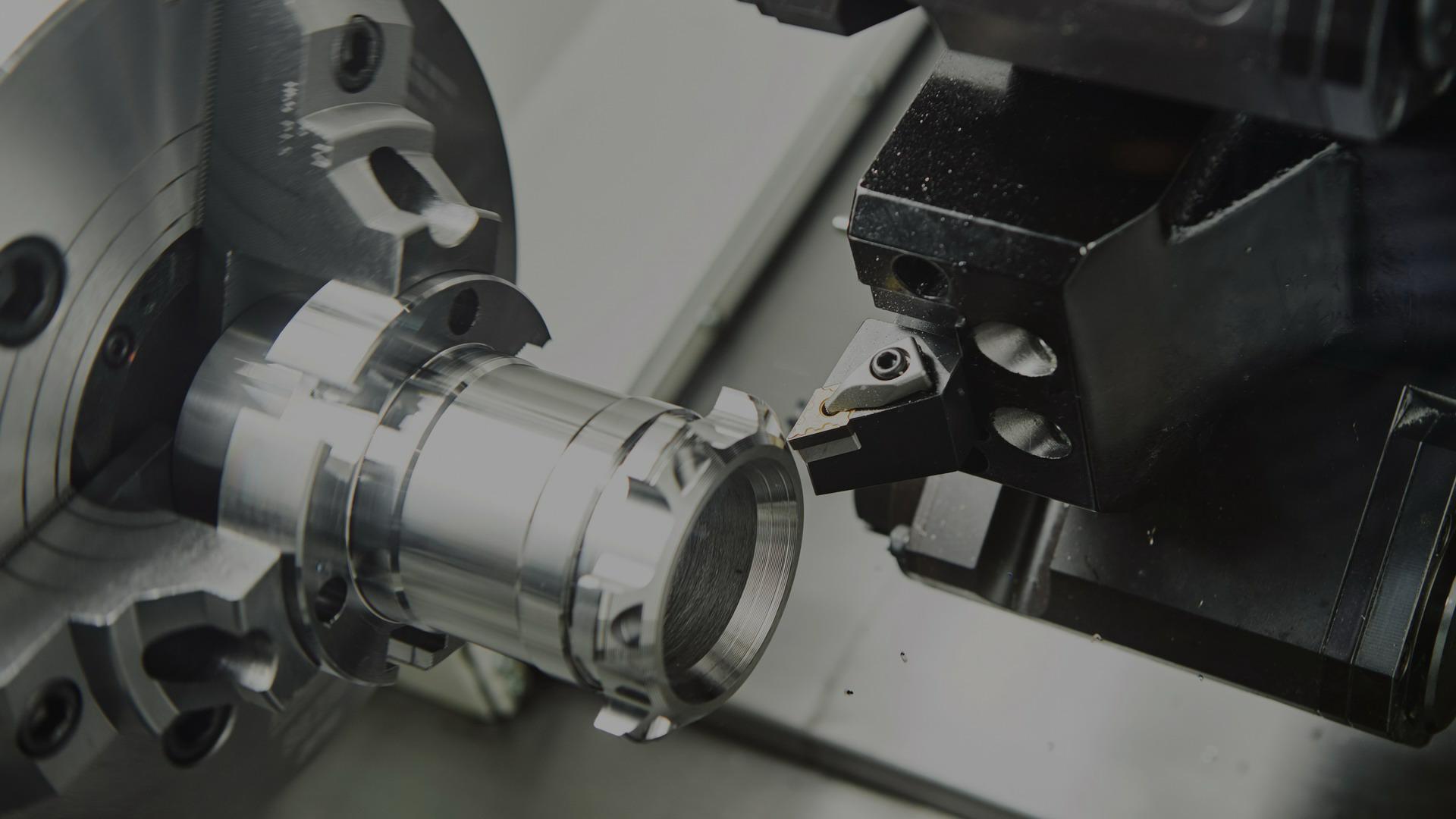

The Rise of CNC Turning Centers in Modern Manufacturing

CNC turning centers represent a significant leap from traditional lathes and manual machining processes. By integrating computer numerical control (CNC) technology, these machines automate and optimize the turning process, delivering unmatched accuracy, repeatability, and speed. At Xilici (XLC), CNC turning centers have become the backbone of their CNC machining operations, enabling the company to produce complex components with tight tolerances and superior surface finishes.

Key Features of CNC Turning Centers

- Multi-axis capabilities for intricate geometries

- Automated tool changers for uninterrupted production

- Live tooling options for combined milling and turning

- Advanced sensors for real-time monitoring and feedback

These features not only boost productivity but also minimize human error, ensuring that every part produced at XLC’s CNC machining factory meets the highest standards of quality.

How XLC Leverages CNC Turning Centers for Precision Machining

Xilici (XLC) has invested heavily in state-of-the-art CNC turning centers, recognizing their potential to transform both prototyping and high-volume production. Here’s how XLC is leveraging these machines:

injection molding

urethane casting

precision machining

- Rapid Prototyping: XLC can quickly turn digital designs into physical prototypes, allowing for faster product development and testing cycles.

- High-Volume Production: With automation and multi-tasking capabilities, XLC’s CNC machining factory can handle large orders with consistent quality and minimal downtime.

- Complex Part Manufacturing: The precision of CNC turning centers enables XLC to manufacture parts with intricate features, tight tolerances, and challenging materials.

By continually upgrading their equipment and training their workforce, XLC ensures they remain at the cutting edge of CNC machining technology.

Industry Impact: The Broader Benefits of CNC Turning Centers

The adoption of CNC turning centers is not just a boon for Xilici (XLC); it’s reshaping the entire manufacturing landscape. Here are some industry-wide benefits:

1. Enhanced Product Quality

CNC turning centers deliver exceptional precision, which translates to higher quality finished products. This is especially critical in sectors like aerospace, automotive, and medical devices, where even minor deviations can have significant consequences.

2. Increased Production Efficiency

Automated tool changes, multi-axis machining, and real-time monitoring allow CNC machining factories to operate around the clock, reducing lead times and increasing throughput. For companies like XLC, this means faster delivery to clients and the ability to take on more complex projects.

3. Cost-Effectiveness

While the initial investment in CNC turning centers can be substantial, the long-term savings are significant. Reduced labor costs, less material waste, and fewer errors all contribute to a lower cost per part—savings that XLC can pass on to their customers.

Integrating CNC Machining with Digital Manufacturing Trends

Today’s manufacturing environment is driven by digital transformation. CNC turning centers are a perfect fit for this trend, as they seamlessly integrate with CAD/CAM software, IoT-enabled monitoring systems, and data analytics platforms. At XLC, digital manufacturing is not just a buzzword—it’s a daily reality. Engineers can remotely monitor machine performance, adjust parameters in real time, and even predict maintenance needs before downtime occurs.

Smart Factories and the Future of CNC Machining

The concept of the “smart factory” is becoming a reality, with CNC machining factories like Xilici (XLC) leading the way. By connecting CNC turning centers to a digital ecosystem, XLC can optimize workflows, improve quality control, and respond quickly to changing customer demands. This level of agility is essential in today’s global market, where customization and rapid turnaround are key competitive advantages.

Industry Insights: CNC Machining’s Role in Emerging Sectors

The influence of CNC machining, particularly with advanced turning centers, is expanding into new and emerging industries. For example, the electric vehicle (EV) sector relies on high-precision components for motors and battery systems—parts that XLC can manufacture efficiently and accurately. Similarly, the rise of medical device miniaturization demands the kind of micro-machining capabilities that only state-of-the-art CNC turning centers can provide.

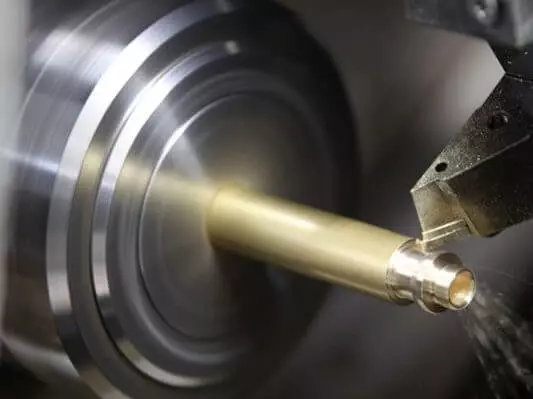

Comparing Traditional vs. CNC Turning

| Aspect | Traditional Turning | CNC Turning Center |

|---|---|---|

| Precision | Manual, operator-dependent | Automated, highly consistent |

| Speed | Slower, limited by manual input | Fast, continuous operation |

| Complexity | Limited to simple shapes | Handles complex geometries |

| Cost | Lower initial, higher long-term | Higher initial, lower long-term |

Why Choose Xilici (XLC) as Your CNC Machining Partner?

With decades of experience and a relentless commitment to innovation, Xilici (XLC) stands out as a premier CNC machining factory. Their investment in advanced CNC turning centers, coupled with a skilled workforce and a digital-first approach, allows them to deliver solutions that exceed client expectations.

- ISO-certified quality management systems

- Comprehensive material capabilities (metals, plastics, composites)

- Flexible production—from prototypes to mass manufacturing

- Responsive customer service and technical support

For businesses seeking reliable, high-quality CNC machining services, XLC’s blend of technology and expertise makes them an ideal partner.

Conclusion: The Future of Precision Machining

CNC turning centers are more than just machines—they are the engines driving the next wave of industrial innovation. At Xilici (XLC), these advanced tools are unlocking new levels of precision, efficiency, and flexibility, helping clients stay ahead in a competitive marketplace. As digital manufacturing, automation, and smart factory concepts continue to evolve, the role of CNC machining will only become more central to industry success.

Whether you’re developing cutting-edge products or looking to streamline your manufacturing operations, partnering with a forward-thinking CNC machining factory like XLC ensures you have the technology and expertise needed to turn your vision into reality.