How Can Mold Making OEM Revolutionize Your Product Design

In today’s fiercely competitive manufacturing landscape, product innovation and efficiency are more critical than ever. Companies are seeking ways to streamline their design-to-production processes, reduce costs, and stay ahead of market trends. Mold making OEM (Original Equipment Manufacturing) services, particularly from industry leaders like xilici company (XLC), have emerged as a transformative force in product design and manufacturing. This article explores how mold making OEM can revolutionize your product design, with a focus on the latest industry trends and the integration of advanced technologies such as cnc machining parts and custom cnc machining.

Understanding Mold Making OEM and Its Role in Product Design

Mold making OEM involves the design and manufacture of molds that are used to produce components or products in large quantities. These molds are essential for industries such as automotive, electronics, medical devices, and consumer goods. By partnering with a reputable mold making OEM like XLC, companies can leverage specialized expertise, state-of-the-art technology, and a streamlined production process.

injection molding

custom extrusion

rapid tooling

The XLC Advantage: Expertise and Innovation

xilici company (XLC) stands out in the mold making OEM sector for its commitment to quality, innovation, and customer satisfaction. With years of experience and a highly skilled engineering team, XLC delivers customized mold solutions that cater to diverse industry requirements. Their approach combines traditional craftsmanship with cutting-edge digital technologies, ensuring precision and consistency in every project.

The Impact of Mold Making OEM on Product Design

Accelerating the Design-to-Production Cycle

One of the most significant advantages of working with a mold making OEM is the acceleration of the design-to-production cycle. XLC utilizes advanced simulation software and rapid prototyping techniques to validate product designs before full-scale production. This reduces the risk of costly errors and enables faster iterations, allowing companies to bring products to market more quickly.

Enhancing Product Quality and Consistency

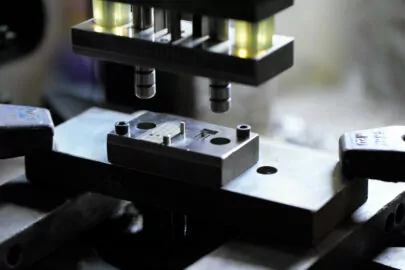

Precision is paramount in modern manufacturing. XLC employs high-precision cnc machining parts in the mold making process, ensuring that each mold meets exact specifications. The use of custom cnc machining allows for intricate designs and tight tolerances, resulting in products that are both high-quality and consistent across large production runs.

Integrating CNC Machining Parts into Mold Making

CNC (Computer Numerical Control) machining has become an integral part of mold making. By integrating cnc machining parts into the OEM process, XLC can produce complex geometries and fine details that were previously difficult or impossible to achieve. This opens up new possibilities for product design, enabling the creation of innovative and functional components.

Benefits of Custom CNC Machining in Mold Making

- Design Flexibility: Custom cnc machining allows for the production of unique, intricate features tailored to specific product requirements.

- Material Versatility: CNC machines can work with a wide range of materials, including metals, plastics, and composites, giving designers more options.

- Reduced Lead Times: Automated CNC processes speed up mold production, reducing time-to-market for new products.

- Cost Efficiency: Precision machining reduces material waste and minimizes the need for post-processing.

By leveraging these benefits, XLC helps clients achieve superior product performance and aesthetics while maintaining cost-effectiveness.

Industry Trends: Digitalization and Smart Manufacturing

Embracing Industry 4.0

The manufacturing industry is undergoing a digital transformation, often referred to as Industry 4.0. Technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics are being integrated into production lines to enhance efficiency, traceability, and quality control. XLC is at the forefront of this revolution, adopting smart manufacturing practices to optimize mold making processes.

- Real-Time Monitoring: IoT-enabled machines provide real-time data on production status, enabling proactive maintenance and reducing downtime.

- Predictive Analytics: AI algorithms analyze production data to predict potential issues and recommend process improvements.

- Digital Twins: Virtual replicas of molds and production systems allow for advanced simulation and optimization before physical manufacturing begins.

These innovations not only improve product quality but also create a more agile and responsive manufacturing environment.

Collaboration and Customization: The XLC Approach

Customer-Centric Design Process

At XLC, collaboration is at the heart of every project. The company works closely with clients from the initial concept stage through to final production, ensuring that all design requirements are met. This customer-centric approach allows for the development of highly customized solutions, including custom cnc machining for specialized components.

Steps in XLC’s Collaborative Design Process

- Consultation: Understanding client needs, product functionality, and market requirements.

- Design & Simulation: Utilizing CAD/CAM software and simulation tools to refine mold and product designs.

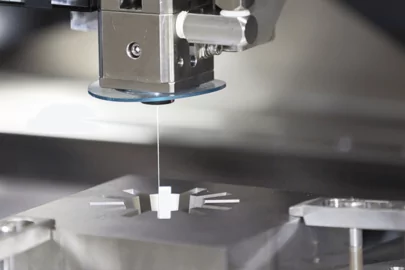

- Prototyping: Creating prototypes using rapid tooling and cnc machining parts for validation and testing.

- Production: Full-scale manufacturing using high-precision equipment and quality control systems.

- Post-Production Support: Providing ongoing support, maintenance, and optimization services.

This methodology ensures that every mold and product meets the highest standards of performance and reliability.

Industry Insights: The Future of Mold Making OEM

The mold making OEM industry is expected to grow significantly in the coming years, driven by increasing demand for customized products, rapid prototyping, and advanced manufacturing technologies. As industries such as automotive, aerospace, and medical devices push for greater innovation, the role of companies like XLC becomes even more crucial.

- Automotive: Lightweight materials and complex geometries require advanced mold making and custom cnc machining capabilities.

- Medical Devices: Precision and reliability are non-negotiable, making high-quality molds essential for success.

- Consumer Electronics: Miniaturization and intricate designs necessitate cutting-edge manufacturing solutions.

To stay competitive, manufacturers must embrace the latest technologies and partner with experienced OEMs who can deliver tailored solutions.

Conclusion: Transforming Product Design with XLC Mold Making OEM

Mold making OEM services from xilici company (XLC) are revolutionizing the way products are designed and manufactured. By combining expertise in mold engineering, advanced technologies like cnc machining parts and custom cnc machining, and a customer-focused approach, XLC empowers companies to innovate faster, improve product quality, and reduce costs. As the industry evolves, partnering with a forward-thinking OEM like XLC is the key to unlocking new possibilities in product design and manufacturing.

Are you ready to take your product design to the next level? Discover how XLC’s mold making OEM solutions can transform your ideas into reality and keep you ahead of the competition.