In-Depth Guide to CNC Metal Cutting Machine Procurement for U.S. Engineering Buyers

——FAQs on Material Selection, Anti-Corrosion, OEM Customization, and Factory Audits

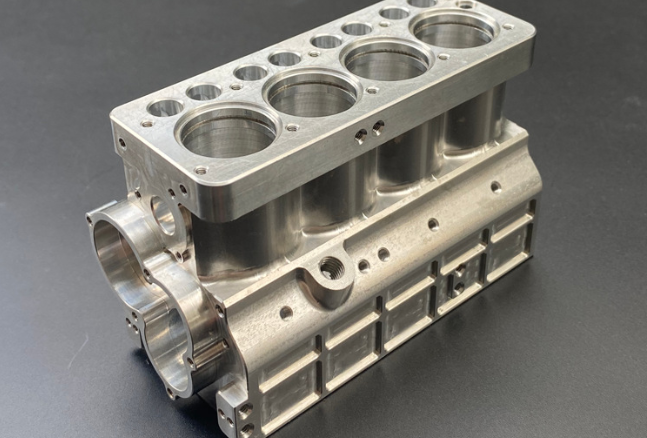

I. Material Comparison: How to Choose the Right Metal?

Q1: What are the pros and cons of common metals in CNC machining?

Based on industry data, here’s a performance comparison of popular metals:

- Material Advantages Disadvantages Typical Applications Case Studies

- Aluminum

Lightweight, excellent thermal conductivity, easy to machine

Low hardness, poor wear resistance

Aerospace components, electronics casings

Apple’s CNC-machined iPhone metal casings

Stainless Steel

Corrosion-resistant, high strength

High machining difficulty, rapid tool wear

Medical devices, chemical containers

Kennametal’s Romicron® boring system for precision machining

Titanium Alloy

High strength, heat resistance, biocompatibility

High cost, requires specialized tools

Medical implants, jet engine parts

Absolute Machining’s titanium firearm components

Brass

Superior conductivity, low magnetism

Prone to oxidation, low strength

Electrical connectors, plumbing fixtures

Precision brass instrument machining cases

Carbon Steel

Cost-effective, highly malleable

Requires anti-rust treatments

Structural frameworks, mechanical parts

MetLab’s economical cutting solutions

Recommendations:

High Precision: Prioritize aluminum or titanium with carbide tools (e.g., Kennametal’s Beyond™ inserts).

Budget Constraints: Use carbon steel or stainless steel with coatings to balance cost and performance.

Q2: How to select a plasma cutter based on material thickness?

Plasma cutter selection must align with material thickness and cutting speed:

- Thin Sheets (<10mm): Opt for ≤60A machines (e.g., OMNI cutters) with speeds up to 5000mm/min, ideal for signage and decorative parts.

- Medium-Thick Plates (10-30mm): Choose 100-200A models (e.g., Hypertherm Powermax) with high-pressure cooling systems.

- Extra-Thick Plates (>30mm): Use 200A+ machines (e.g., Coherent METABEAM 1000) with nitrogen/oxygen assist to prevent slag adhesion.

Technical Insights:

- Cutting Accuracy: ±0.1mm (laser) vs ±0.5mm (plasma).

- Operational Cost: Plasma consumes 30% less energy but requires frequent consumable replacements6.

II. Anti-Corrosion: Extending Component Lifespan

Q3: What anti-corrosion treatments are available for CNC parts?

- Process Materials Effectiveness Cost Case Studies

- Anodizing Aluminum Corrosion resistance, color options, hardness boost Medium Apple’s secondary anodizing for iPhone casings

- Electroplating Steel/Stainless Rust prevention, wear resistance High EnPai’s anti-corrosion machinery bodies

- Passivation Stainless/Titanium Removes surface iron, enhances oxide layer Low Medical device sterilization standards

- Powder Coating Multi-material Eco-friendly, color variety Medium Outdoor structural component protection

Key Notes:

Anodizing Thickness: ≥10μm recommended for industrial environments.

Coating Compatibility: Verify compatibility with post-processing (e.g., welding) to avoid peeling.

Q4: How to minimize oxidation during cutting?

- Coolant Selection:

- Water-based: Suitable for aluminum but requires regular replacement (e.g., MetLab’s 9L circulation system).

- Oil-based: Better lubrication for stainless steel but requires fireproofing.

- Gas Shielding: Use nitrogen or argon during plasma cutting to reduce oxidation

III. OEM Customization: Streamlining Collaboration

Q5: What is the typical OEM workflow for U.S. manufacturers?

- Standard Process (e.g., Absolute Machining):

- Requirement Clarification: Provide 3D designs or samples, specifying material, tolerance (±0.025mm), and surface finish.

- DFM Review: Supplier feedback on manufacturability (e.g., simplifying complex structures to reduce costs).

- Prototyping: Validate processes using high-speed drilling centers (e.g., LUNYEE 3018 Pro Max)1.

- Mass Production Agreement: Sign NDAs, confirm lead times (2-4 weeks), and quality standards (e.g., ISO 2768).

- Logistics & After-Sales: Offer FOB/DDP terms with return policies and technical support.

- Cost-Saving Tips:

- Bulk Pricing: 500+ units reduce per-unit costs by 20-30%.

- Standardized Design: Minimize non-standard fixtures (e.g., Avid CNC’s smart spindle system)

Q6: How to protect intellectual property during customization?

Legal Measures: Sign NDAs defining data ownership and breach penalties.

Technical Safeguards: Request dedicated production lines (e.g., Vantage Point Armory’s isolated workshops).

IV. Factory Audits: Selecting Reliable Suppliers

Q7: What critical machine parameters should be inspected?

- Positioning Accuracy ≤±0.01mm (e.g., MetLab cutters) Laser interferometer measurement

- Spindle Speed ≥12,000 RPM (high-precision needs) Check equipment nameplates and logs

- Cooling System High-pressure cooling (≥120 Bar) Inspect coolant pressure gauges

- Safety Certifications ISO 9001/AS9100 (aerospace standards) Verify certification documents

Q8: How to mitigate risks through supply chain audits?

- Material Traceability: Demand raw material certifications (e.g., Kennametal’s Beyond™ inserts)9.

- Capacity Verification: Assess automation levels (e.g., GRBL offline control stability)1.

- Contingency Plans: Ensure redundant equipment (e.g., Avid CNC’s quick-change spindle design)

V. Extended Resources

- Free Tools: Use Google Keyword Planner for trend analysis.

- Advanced Software: Implement Vericut for toolpath validation to reduce trial cuts and enable unmanned production.

- Case Study: Tri-Mack Plastics reduced lead times by 40% using Vericut, achieving GE Aviation’s Supplier Quality Award