Quick Solution for Mechanical Parts – Powder Metallurgy

Introduction

In the ever-evolving landscape of manufacturing, the demand for innovative solutions for mechanical parts is at an all-time high. Powder metallurgy (PM) has emerged as a go-to process that offers a host of benefits ranging from enhanced material properties to cost-effectiveness. This article delves deep into the various aspects of powder metallurgy, including its process flow, industry applications, metal attributes, hardness characteristics, the convenience of CNC machining, and the advantages of finished products.

Understanding Powder Metallurgy

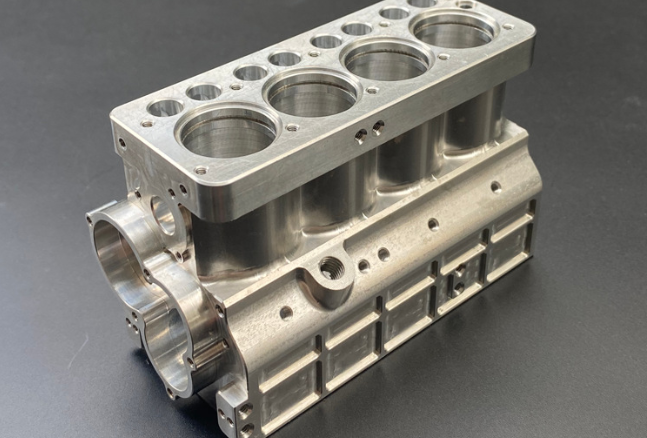

Powder metallurgy is an advanced material forming manufacturing process whose core technical workflow comprises two critical stages: metal powder preparation and powder forming. This process first involves producing metal powder raw materials with specific particle size distributions and morphological characteristics through specialized techniques such as atomization, reduction, or electrolysis. Subsequently, pressure processing technologies like precision die pressing, isostatic pressing, or metal injection molding are employed, combined with high-temperature sintering, to ultimately transform loose powders into dense metal components with excellent mechanical properties.

The Process Flow of Powder Metallurgy

The powder metallurgy process can be broken down into several key stages:

- Powder Production: The first step involves producing metal powders. Various methods such as atomization, milling, and reduction are employed to generate powders with specific characteristics like particle size and morphology.

- Blending: Once the powders are produced, they are often blended with additives to enhance properties such as flowability, strength, and oxidation resistance.

- Compaction: The blended powders are then compacted into a desired shape using high pressure in dies. This step is crucial as it determines the initial geometrical form of the part.

- Sintering: The compacted parts are subsequently sintered in a controlled atmosphere furnace. This stage involves heating below the melting point of the material, which promotes particle bonding and densification.

- Finishing Operations: Finally, additional processes like machining, heat treatment, or surface finishing may be applied to achieve desired dimensional tolerances and enhance performance.

Industry Applications of Powder Metallurgy

Powder metallurgy finds applications across various industries, owing to its ability to manufacture complex components with high precision. Some predominant sectors include:

Powder metallurgy has become the manufacturing method of choice for critical mechanical components such as precision gears, high-performance bearings, and automotive camshafts due to its unique ability to produce parts with superior strength-to-weight ratios. The process enables the creation of near-net-shape components that maintain exceptional structural integrity while being significantly lighter than their traditionally manufactured counterparts.

For gear applications, PM technology allows for the production of complex tooth geometries with consistent density distribution, resulting in components that exhibit excellent wear resistance and fatigue strength. The self-lubricating properties achievable through PM further enhance gear performance in demanding applications. Similarly, PM bearings benefit from controlled porosity that can be impregnated with lubricants, providing long-lasting performance with minimal maintenance requirements.

In automotive applications, PM camshafts demonstrate remarkable advantages in terms of dimensional precision and weight reduction. The ability to consolidate multiple parts into a single component reduces assembly requirements while improving overall engine efficiency. These weight-optimized components contribute directly to fuel economy improvements and reduced emissions in modern vehicles.

The technology’s material efficiency also makes it particularly valuable for these applications, as it minimizes machining waste for components that would otherwise require extensive material removal from solid billets. This combination of performance characteristics and manufacturing efficiency explains why PM has become indispensable for producing these critical mechanical elements across industries ranging from automotive to aerospace and industrial machinery.

The technology is particularly transformative for critical components like aircraft turbine blades and aerospace structural elements, where every gram of weight reduction translates directly into enhanced performance and energy efficiency.

For turbine applications, PM enables the production of blades with precisely controlled internal cooling channels and optimized airfoil geometries that would be impossible to machine conventionally. The process creates components with uniform microstructure and minimized material defects, resulting in superior fatigue resistance at extreme temperatures. Aerospace structural parts benefit similarly, with PM allowing for complex lattice structures and topology-optimized designs that maintain structural integrity while achieving unprecedented weight savings.

The automotive sector equally capitalizes on these advantages, employing PM for suspension components, connecting rods, and transmission parts that require both durability and mass reduction. The technology’s capacity to produce near-net-shape parts with tailored material properties eliminates the need for excessive machining of high-strength alloys, significantly reducing production costs while improving performance characteristics.

What makes PM indispensable for these applications is its unique combination of material efficiency and design flexibility. Engineers can precisely control porosity levels, incorporate multiple materials in a single component, and create graded structures that transition smoothly between different material properties – capabilities that conventional manufacturing methods simply cannot match. This explains why industries pushing the boundaries of performance, from motorsports to renewable energy systems, are increasingly specifying powder metallurgy for their most demanding mechanical components.

- Electronics:

Powder metallurgy has revolutionized the production of advanced electromagnetic components, enabling unprecedented design freedom and performance characteristics. The technology excels at manufacturing complex soft magnetic cores for electric motors and transformers, where precisely controlled porosity and grain structure optimize magnetic flux paths while minimizing eddy current losses.

For precision electrical applications, PM facilitates the creation of intricate contact systems and miniature circuit breaker components with superior arc resistance. The process allows for the integration of multiple materials in a single part – combining conductive elements with insulating sections or embedding permanent magnets within rotor assemblies. This multi-material capability is particularly valuable for sensor components and micro-actuators used in automotive and aerospace systems.

The technology’s dimensional accuracy proves critical when producing the fine-pitch gear teeth in stepper motors or the complex pole geometries in brushless DC motors. PM’s net-shape manufacturing eliminates the need for secondary machining of these delicate features, preserving the material’s magnetic properties while maintaining tight tolerances down to ±0.05mm.

Recent advancements in binder jetting and metal injection molding have further expanded PM’s role in electromagnetic applications, enabling the production of ultra-thin laminations and three-dimensional flux guides that push the boundaries of energy efficiency in modern electrical systems. These capabilities make powder metallurgy indispensable for next-generation power electronics, renewable energy systems, and miniaturized electromechanical devices.

- Medical Devices:

Powder metallurgy has emerged as a transformative manufacturing approach for medical applications, particularly in the production of patient-specific implants and high-performance surgical instruments. The technology enables the fabrication of titanium and cobalt-chrome alloy implants with precisely controlled porous structures that promote osseointegration while matching the patient’s unique anatomical requirements.

For orthopedic applications, PM allows the creation of femoral stems and acetabular cups with gradient porosity – dense cores for structural integrity transitioning to porous surfaces that facilitate bone ingrowth. The process can incorporate bioactive coatings during sintering, creating implants that actively stimulate tissue regeneration. Dental implants similarly benefit from PM’s ability to produce root forms with optimized surface textures and internal channels for improved stability and nutrient transport.

In surgical instrumentation, PM techniques manufacture razor-sharp scalpel blades with superior edge retention and corrosion resistance. The technology produces complex laparoscopic tool components with internal articulating mechanisms in a single manufacturing step, eliminating assembly requirements. PM’s material consistency ensures every instrument meets exacting surgical standards for reliability and precision.

The medical field particularly values PM’s capacity for producing fully sterilizable components with exceptional cleanliness – critical for implants that must remain in the body for decades. Recent advances in additive powder metallurgy now enable the production of patient-matched cranial plates and spinal cages with anatomical accuracy down to 0.1mm, revolutionizing reconstructive surgery outcomes.

Metal Attributes Achieved Through Powder Metallurgy

The properties of metals produced through powder metallurgy can be superior to those created via traditional methods. Some noteworthy attributes include:

- Uniform Microstructure:

Powder metallurgy components demonstrate superior material homogeneity that directly enhances their operational reliability and service life. Unlike conventional cast or wrought materials, PM parts benefit from meticulously controlled particle distribution and sintering parameters that eliminate directional grain structures and minimize microscopic defects. This results in isotropic mechanical characteristics where strength, ductility, and fatigue resistance remain consistent regardless of load orientation.

The uniform microstructure achieved through PM processing provides several critical performance advantages. First, the elimination of segregation defects common in traditional metallurgy leads to more predictable stress distribution under load. Second, the fine, equiaxed grain structure enhances both yield strength and fracture toughness simultaneously – a combination difficult to achieve through other manufacturing methods. Third, the controlled porosity inherent in PM parts can be engineered to serve specific functions, whether for oil retention in bearings or as pathways for bone ingrowth in medical implants.

These microstructural benefits manifest in real-world applications as extended component life, reduced failure rates, and improved performance consistency across production batches. For high-stress applications like automotive transmission gears or aircraft braking systems, this material uniformity translates directly into enhanced safety margins and maintenance intervals. The technology’s ability to maintain this consistency while accommodating complex geometries makes PM indispensable for critical components where both performance and reliability are paramount.

- Controlled Porosity:

Powder Metallurgy Enables Precision Engineering of Porous Structures for Advanced Applications

Powder metallurgy’s unique capability to precisely control material porosity has opened new frontiers in functional component design. Unlike conventional manufacturing methods, PM technology allows engineers to dial in exact porosity levels ranging from 5% to 70% with pore sizes adjustable between 5-100 microns – a level of precision that creates tailored solutions for demanding filtration and catalytic applications.

In filtration systems, PM-produced components demonstrate unparalleled performance:

- Multi-level porous filters with gradient density structures that achieve 99.97% particulate removal while maintaining optimal flow rates

- High-temperature gas filters for turbine inlets featuring thermally stable pore networks that withstand operating temperatures exceeding 800°C

- Self-cleaning filter media with interconnected porosity that enables backflushing without structural compromise

For catalytic applications, PM facilitates:

- Three-dimensional catalyst substrates with optimized surface-area-to-volume ratios that maximize reaction efficiency

- Functionally graded catalyst carriers that progressively change porosity to control reaction kinetics along the flow path

- Composite catalytic structures that combine porous metal frameworks with ceramic coatings for enhanced thermal stability

The technology’s ability to engineer both open and closed porosity within the same component makes it particularly valuable for:

- Fuel cell components requiring carefully balanced gas diffusion and structural support layers

- Medical implants needing surface porosity for tissue integration combined with solid cores for load bearing

- Acoustic dampers utilizing precisely tuned pore structures for frequency-specific sound absorption

Recent advances in PM pore architecture control now enable the production of hierarchical porous structures that mimic natural materials like bone or coral, pushing the boundaries of what’s possible in mass transport applications while maintaining exceptional mechanical properties.

CNC Machining Convenience

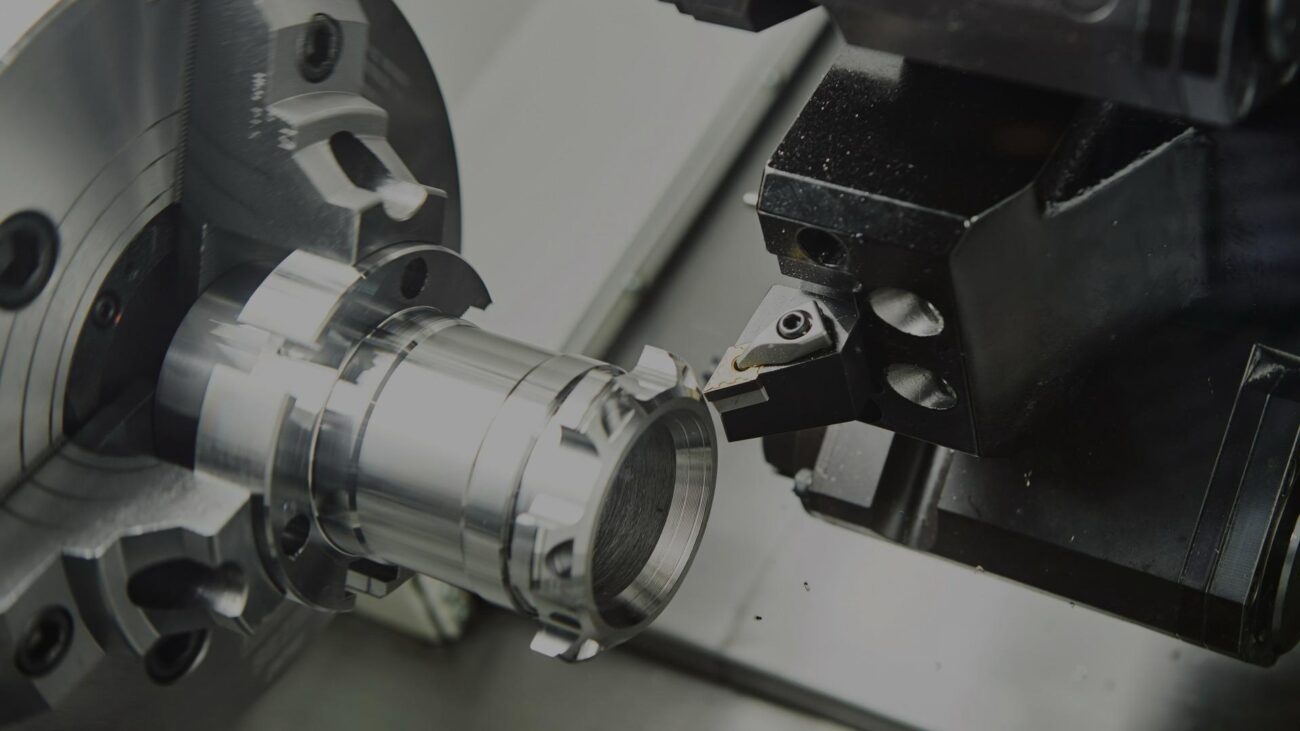

CNC (Computer Numerical Control) machining has revolutionized how powder metallurgy parts are processed. Benefits include:

Precision:

CNC machining sets the gold standard for manufacturing precision, enabling the production of components with tolerances as tight as ±0.005 mm (±0.0002 inches). This exceptional accuracy ensures flawless compatibility with mating parts and strict adherence to ISO, ASME, and other critical industry specifications.

The technology’s computer-controlled process eliminates human error while maintaining repeatable precision across production runs—whether crafting complex aerospace components, medical implants, or high-performance automotive parts. Advanced CNC systems combine rigid machine construction with high-resolution feedback controls to achieve surface finishes under 0.4 μm Ra, surpassing conventional machining capabilities.

From micro-machined electronics to massive industrial components, CNC delivers the dimensional perfection demanded by today’s most exacting applications while optimizing production efficiency. This combination of precision and reliability makes CNC machining indispensable for mission-critical parts where “close enough” simply isn’t an option.

Complex Geometries:

Modern CNC technology unlocks unprecedented design freedom, transforming complex 3D geometries—including organic shapes, micro-features, and high-precision contours—into tangible reality. Five-axis machining centers and mill-turn systems now routinely produce:

- Biomimetic surfaces with controlled texture patterns down to 5μm resolution

- Monolithic components integrating what previously required 10+ assembled parts

- Thin-wall structures under 0.1mm thick with ±0.01mm dimensional stability

This capability revolutionizes industries from medical (patient-specific implants with porous bone-mimicking structures) to aerospace (fuel nozzles with optimized internal channels). By combining sub-micron precision with advanced toolpath strategies, contemporary CNC systems effectively erase the line between “design intent” and “manufacturable reality.”

The technology’s true breakthrough lies in achieving these complex geometries while maintaining production-grade speeds and repeatability—making the previously “unmakable” not just possible, but commercially viable.

Increased Efficiency

Modern CNC systems slash production timelines by 40-60% through:

- Seamless digital workflows from CAD to finished part

- Lights-out machining capabilities for 24/7 operation

- High-speed machining at 50,000+ RPM spindle speeds

- Automated tool changers reducing setup time by 80%

The technology’s smart automation maintains micron-level accuracy while achieving throughput previously requiring multiple conventional machines. This dual advantage of accelerated production and uncompromised precision makes CNC the backbone of Industry 4.0 manufacturing.

For time-sensitive industries like automotive and aerospace, CNC integration transforms weeks-long processes into days while improving first-pass yield rates above 99%. The result? Faster time-to-market without quality tradeoffs.

Conclusion

As the demand for efficient and high-performance mechanical parts continues to grow across various industries, powder metallurgy stands out as a premier manufacturing solution. From its intricate process flow to the numerous benefits of finished products, PM not only satisfies the current market demands but also paves the way for future innovations in manufacturing. By leveraging advanced technologies like CNC machining and focusing on material attributes, industries can harness the full potential of powder metallurgy to create robust, cost-effective, and sustainable mechanical parts.