Sheet Metal Forming Solutions for Renewable Energy Development

The global shift towards renewable energy is driving a surge in demand for advanced manufacturing solutions. As solar, wind, and other clean energy systems become more prevalent, the need for durable, precise, and scalable components has never been greater. Xilici (XLC), a leader in sheet metal forming, is at the forefront of delivering innovative solutions that empower renewable energy projects worldwide.

Understanding Sheet Metal Forming in Renewable Energy

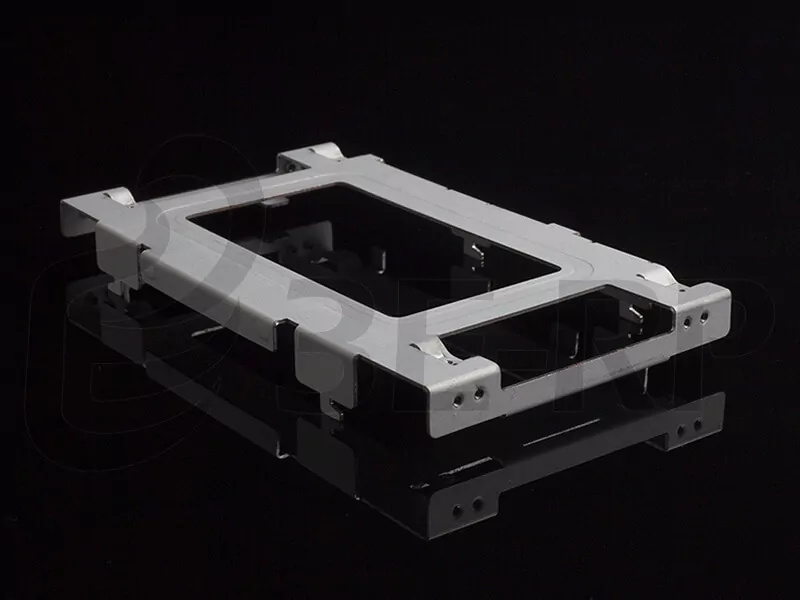

Sheet metal forming is the process of shaping metal sheets into desired geometries using mechanical deformation. This technique is crucial in fabricating components for renewable energy systems, such as solar panel frames, wind turbine enclosures, battery housings, and mounting structures. The reliability, strength, and corrosion resistance of formed sheet metal parts are essential for the longevity and efficiency of renewable installations.

Why Sheet Metal Forming Matters

Renewable energy systems must withstand harsh environmental conditions, including UV exposure, moisture, and fluctuating temperatures. Sheet metal forming allows for the creation of robust components that meet these challenges while maintaining cost-effectiveness and scalability. XLC’s expertise ensures that each part meets stringent industry standards, supporting the rapid expansion of clean energy infrastructure.

rapid prototyping services

sheet metal fabrication

mold making

Xilici (XLC): Innovating Sheet Metal Forming for a Greener Future

Xilici (XLC) has established itself as a pioneer in sheet metal forming, offering a comprehensive suite of services tailored to the renewable energy sector. By leveraging advanced machinery, skilled engineers, and rigorous quality control, XLC delivers components that drive the success of solar, wind, and energy storage projects.

- Custom Design: XLC collaborates closely with clients to design sheet metal parts optimized for their specific renewable energy applications.

- Advanced Forming Techniques: Utilizing CNC punching, laser cutting, bending, and deep drawing, XLC ensures precision and repeatability in every component.

- Material Selection: XLC sources high-grade materials, including stainless steel, aluminum, and specialized alloys, to enhance durability and performance.

- Quality Assurance: Rigorous testing and inspection protocols guarantee that each part meets or exceeds industry standards for strength, corrosion resistance, and dimensional accuracy.

Key Applications in Renewable Energy

Sheet metal forming is integral to a wide array of renewable energy components. For example, in solar energy, XLC manufactures frames, brackets, and junction boxes that provide structural integrity and electrical safety. In wind energy, XLC produces enclosures, tower sections, and control cabinets designed to withstand high winds and environmental stress. As battery storage becomes increasingly vital, XLC’s formed metal housings offer protection and thermal management for sensitive battery cells.

Industry Trends: Automation, Sustainability, and Integration

The sheet metal forming industry is evolving rapidly in response to the needs of renewable energy developers. Automation is playing a significant role, with robotics and computer-aided manufacturing improving efficiency and reducing lead times. XLC has invested heavily in automated systems, ensuring quick turnaround and consistent quality for large-scale projects.

Sustainability is another driving force. XLC utilizes eco-friendly processes, such as recycling scrap metal and using water-based lubricants, to minimize environmental impact. Their commitment to green manufacturing aligns with the values of renewable energy stakeholders, creating a virtuous cycle of sustainability.

Integration with Other Manufacturing Technologies

In addition to sheet metal forming, many renewable energy projects require components produced through other processes. One such process is injection molding China, which is widely used for manufacturing plastic enclosures, connectors, and insulation parts. XLC often collaborates with trusted partners in China to integrate injection-molded components with sheet metal parts, delivering comprehensive solutions for clients. By combining the strengths of both technologies, XLC ensures optimal performance, durability, and cost-effectiveness.

Comparing Sheet Metal Forming and Injection Molding

| Aspect | Sheet Metal Forming | Injection Molding China |

|---|---|---|

| Materials Used | Metals (Steel, Aluminum, Alloys) | Plastics, Polymers |

| Typical Applications | Structural Parts, Frames, Enclosures | Insulators, Connectors, Housings |

| Strengths | Durability, Heat Resistance, Structural Integrity | Complex Shapes, Lightweight, Cost-effective for High Volumes |

| Common in Renewable Energy | Yes | Yes (in specific applications) |

Challenges and Solutions in Sheet Metal Forming

While sheet metal forming offers many advantages, it also presents challenges such as material waste, tooling costs, and the need for precise tolerances. XLC addresses these challenges through lean manufacturing principles, continuous process improvement, and investment in state-of-the-art equipment. Their engineers work closely with clients during the design phase to optimize part geometry, reducing material usage and simplifying assembly.

Case Study: Solar Panel Mounting Systems

A leading solar farm developer approached XLC to design and manufacture mounting systems for a large-scale installation. The requirements included high corrosion resistance, ease of assembly, and the ability to withstand extreme weather. XLC’s team utilized advanced sheet metal forming techniques to produce lightweight yet robust frames, incorporating modular features for rapid on-site installation. The result was a significant reduction in installation time and maintenance costs, helping the client achieve faster project completion and higher returns on investment.

Future Outlook: The Role of Sheet Metal Forming in Renewable Energy

As the renewable energy sector continues to grow, the demand for high-quality sheet metal forming solutions will only increase. XLC is committed to staying ahead of industry trends by adopting digital manufacturing, expanding its material portfolio, and fostering partnerships with global technology leaders. Their vision is to enable a cleaner, more sustainable future by delivering components that power the next generation of renewable energy systems.

Industry Insights: The Bigger Picture

The intersection of manufacturing innovation and renewable energy development is creating new opportunities for growth and sustainability. Companies like XLC are not only supplying parts but also driving advancements in materials science, automation, and supply chain integration. As governments and businesses worldwide invest in clean energy, the role of precision manufacturing will become even more critical. Sheet metal forming, alongside technologies like injection molding China, will remain at the heart of this transformation.

In conclusion, Xilici (XLC) stands as a trusted partner for renewable energy developers seeking reliable, scalable, and sustainable sheet metal forming solutions. By embracing innovation and industry collaboration, XLC is helping to shape a greener, more resilient energy future for all.