Exploring the Role of Rapid Tooling in Aerospace Innovation

The aerospace industry is synonymous with precision, speed, and relentless innovation. As the demand for lighter, stronger, and more efficient components grows, the methods of manufacturing must evolve. One such transformative approach is rapid tooling. In this article, we explore how Xilici (XLC) is harnessing rapid tooling to drive aerospace innovation, while also touching on the importance of custom injection molding and prototyping services in this high-stakes sector.

Understanding Rapid Tooling in Aerospace Manufacturing

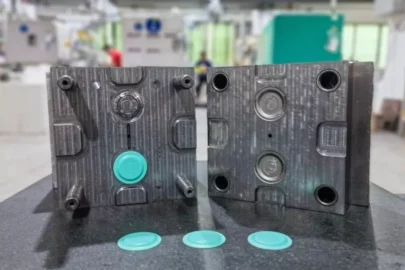

Rapid tooling refers to the process of quickly creating molds and tools that are used in the manufacturing of parts, particularly for prototypes and low-volume production. Unlike traditional tooling, which can take months to fabricate, rapid tooling leverages advanced technologies such as additive manufacturing (3D printing), CNC machining, and hybrid processes to dramatically reduce lead times.

urethane casting

custom extrusion

rapid prototyping services

rapid tooling

For aerospace companies like Xilici (XLC), rapid tooling is not just about speed—it’s about enabling innovation. By shortening the development cycle, engineers can iterate designs more frequently, test new materials, and bring advanced aerospace components to market faster than ever before.

The XLC Approach to Rapid Tooling

Xilici (XLC) has established itself as a leader in integrating rapid tooling into aerospace component production. Their approach combines state-of-the-art equipment, a highly skilled engineering team, and a commitment to quality that meets the rigorous standards of the aerospace industry.

- Advanced Materials: XLC utilizes aerospace-grade materials for rapid tooling, ensuring that prototypes and low-volume parts can withstand the extreme conditions of flight.

- Hybrid Manufacturing: By blending traditional and digital manufacturing, XLC achieves both speed and precision.

- Iterative Prototyping: Rapid tooling allows XLC to deliver multiple design iterations quickly, supporting continuous improvement.

Why Rapid Tooling Matters in Aerospace

Aerospace projects are characterized by their complexity and the need for absolute reliability. Traditional tooling methods are often too slow and inflexible to keep up with today’s pace of innovation. Here’s why rapid tooling is a game-changer:

- Accelerated Development: Rapid tooling slashes the time required to move from design to prototype, enabling faster testing and validation.

- Cost Efficiency: Especially for low-volume and prototype runs, rapid tooling can significantly reduce costs compared to conventional methods.

- Design Flexibility: Engineers can experiment with new geometries and materials, knowing that changes can be implemented quickly.

- Risk Reduction: By enabling more thorough testing early in the process, rapid tooling helps identify and mitigate potential issues before full-scale production.

Custom Injection Molding: Enhancing Aerospace Capabilities

One of the key applications of rapid tooling at XLC is in custom injection molding. Aerospace components often require unique geometries and material properties that standard off-the-shelf parts cannot provide. Rapid tooling enables XLC to produce custom molds for injection molding in a fraction of the time, supporting the rapid prototyping and small-batch production essential to aerospace R&D.

With custom injection molding, XLC can deliver lightweight yet robust components such as brackets, housings, and connectors—each tailored to the specific requirements of a given aircraft or spacecraft. This approach not only accelerates innovation but also ensures that every part meets the highest standards for performance and safety.

Prototyping Services: Turning Ideas into Flight-Ready Solutions

In addition to rapid tooling, XLC offers comprehensive prototyping services for aerospace clients. These services bridge the gap between concept and production, allowing engineers to test form, fit, and function before committing to large-scale manufacturing.

Prototyping services at XLC include 3D printing, CNC machining, and hybrid manufacturing, all supported by advanced design and simulation tools. This integrated approach ensures that prototypes are not only produced quickly but also accurately reflect the final production part, minimizing costly surprises down the line.

Industry Insights: The Broader Impact of Rapid Tooling

The influence of rapid tooling extends far beyond Xilici (XLC). Across the aerospace industry, companies are leveraging this technology to remain competitive in a fast-evolving market. According to recent industry reports, the global aerospace rapid prototyping market is expected to grow at a double-digit CAGR over the next five years, driven by the need for faster innovation cycles and the increasing complexity of aerospace systems.

Major aerospace OEMs and suppliers are investing heavily in digital manufacturing infrastructure, recognizing that rapid tooling is vital for developing next-generation aircraft, satellites, and UAVs. The trend towards electrification in aviation, for example, demands new lightweight components that can be quickly prototyped and tested—a perfect fit for rapid tooling methodologies.

Challenges and Opportunities

Despite its many advantages, rapid tooling also presents challenges. Ensuring the durability and precision of rapidly produced molds requires careful material selection and process control. Additionally, integrating rapid tooling with existing production lines can be complex, particularly in highly regulated industries like aerospace.

However, these challenges are being addressed through advances in materials science, process automation, and digital quality assurance. Companies like XLC are at the forefront of these innovations, continually refining their processes to deliver ever-better results for aerospace clients.

The Future of Aerospace Innovation with Xilici (XLC)

Looking ahead, rapid tooling is set to play an even greater role in shaping the future of aerospace. As the industry pushes the boundaries of what’s possible—from hypersonic flight to commercial space travel—the ability to rapidly design, test, and produce new components will be more important than ever.

Xilici (XLC) is committed to staying ahead of the curve, investing in the latest rapid tooling technologies and expanding its capabilities in custom injection molding and prototyping services. By doing so, XLC empowers aerospace innovators to turn ambitious ideas into reality, faster and more efficiently than ever before.

Conclusion

Rapid tooling is revolutionizing aerospace manufacturing, enabling companies like Xilici (XLC) to accelerate development, reduce costs, and drive innovation. Through advanced custom injection molding and comprehensive prototyping services, XLC is helping to shape the next generation of aerospace technology. As the industry continues to evolve, rapid tooling will remain a cornerstone of progress—ensuring that the sky is not the limit, but just the beginning.