How Injection Molding OEM Shapes the Toy IndustryMoldHow Injection Molding OEM Shapes the Toy Industry

The toy industry has always been a fertile ground for innovation, creativity, and technological advancement. In recent years, one of the most significant influences on this sector has been the evolution of injection molding OEM services. Companies like Xilici Company (XLC) have emerged as key players, transforming how toys are designed, manufactured, and delivered to market. This article explores the critical role of injection molding OEM in shaping the toy industry, with a particular focus on XLC’s pioneering efforts and the broader industry context.

Xilici Company (XLC): At the Forefront of Toy Manufacturing

Founded on the principles of quality, precision, and innovation, Xilici Company (XLC) has established itself as a leading injection molding factory specializing in OEM solutions for the toy industry. By leveraging cutting-edge technology and a highly skilled workforce, XLC delivers custom solutions to toy brands worldwide. Their expertise in injection molding OEM ensures that toy manufacturers can bring intricate designs and safe, durable products to market with unparalleled efficiency.

The Role of Injection Molding OEM in the Toy Industry

Injection molding OEM services have revolutionized the way toys are produced. Instead of relying solely on in-house manufacturing, toy companies now partner with specialized injection molding factories like XLC. This collaboration allows brands to focus on product design and marketing, while XLC handles the complex manufacturing process. The result is faster time-to-market, cost savings, and consistently high product quality.

- Customization: Injection molding OEM enables the production of toys in various shapes, colors, and sizes, catering to diverse consumer preferences.

- Scalability: Factories like XLC can scale production up or down based on demand, ensuring flexibility for toy brands.

- Compliance: XLC’s rigorous quality control ensures that all toys meet international safety standards, addressing concerns about child safety and regulatory compliance.

Why OEM Matters in Today’s Toy Market

The global toy market is fiercely competitive, with brands vying for consumer attention through innovative designs and engaging play experiences. Injection molding OEM services provide a crucial competitive edge. By outsourcing manufacturing to experts like XLC, toy brands can:

- Reduce capital investment in machinery and facilities.

- Access the latest manufacturing technologies without direct R&D costs.

- Improve product consistency and reliability.

- Accelerate product development cycles.

XLC’s injection molding factory is equipped with state-of-the-art machinery and automation systems, ensuring that every toy part produced meets exact specifications. This precision is vital for toys with moving parts, intricate details, or strict safety requirements.

Industry Trends: Sustainability and Smart Toys

As the toy industry evolves, two major trends are shaping the future: sustainability and smart technology integration. Injection molding OEM providers like XLC are at the forefront of these changes, adapting their processes and materials to meet new demands.

Sustainable Manufacturing in Injection Molding

Environmental concerns are driving the adoption of eco-friendly materials and energy-efficient manufacturing processes. XLC has invested in green technologies, such as biodegradable plastics and closed-loop recycling systems, to minimize waste and reduce their carbon footprint. These initiatives not only benefit the environment but also appeal to eco-conscious consumers and retailers.

- Biodegradable plastics: XLC offers options for toys made from materials that break down naturally, reducing landfill impact.

- Energy efficiency: Advanced machinery at XLC’s injection molding factory consumes less energy, lowering operational costs and environmental impact.

Smart Toys and Technological Integration

The rise of smart toys—those with embedded electronics, sensors, or connectivity—has introduced new manufacturing challenges. XLC’s expertise in injection molding OEM allows them to produce complex components that house electronic parts securely and safely. Their ability to integrate precision molding with advanced assembly processes makes them a preferred partner for brands developing the next generation of interactive toys.

XLC’s Process: From Concept to Finished Product

Xilici Company (XLC) follows a comprehensive approach to injection molding OEM, ensuring seamless collaboration with toy brands from initial concept to final delivery. Here’s how the process typically unfolds:

| Stage | Description |

|---|---|

| Design Consultation | XLC’s engineers work with clients to refine toy designs for manufacturability and cost-effectiveness. |

| Prototyping | Rapid prototyping using 3d printing or soft molds allows clients to test and validate their concepts. |

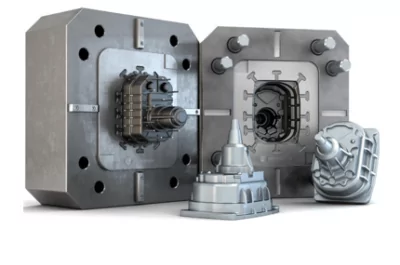

| Mold Fabrication | Precision molds are created using high-grade steel and advanced CNC machines. |

| Injection Molding | The core manufacturing stage, where molten plastic is injected into molds to form toy components. |

| Assembly & Finishing | Parts are assembled, painted, and finished according to client specifications. |

| Quality Control | Rigorous testing ensures each toy meets safety and performance standards. |

| Packing & Shipping | Finished toys are packaged and shipped to global markets. |

Collaboration and Communication

A key strength of XLC’s injection molding OEM service is its collaborative approach. Regular updates, transparent timelines, and open channels of communication ensure that clients are involved at every stage. This partnership model builds trust and delivers superior results.

The Broader Impact: Injection Molding OEM and Industry Evolution

The influence of injection molding OEM extends beyond individual companies like XLC. It is reshaping the entire toy industry by:

- Enabling rapid adaptation to market trends and consumer preferences.

- Lowering barriers to entry for new brands and inventors.

- Promoting global supply chain resilience and efficiency.

- Supporting the transition to sustainable and smart toys.

As a leading injection molding factory, XLC not only serves established brands but also partners with startups and independent designers. Their flexible production capabilities and commitment to innovation make them an engine for growth and creativity in the toy sector.

Challenges and Opportunities

While the benefits of injection molding OEM are clear, the industry faces ongoing challenges, such as fluctuating raw material prices, evolving safety regulations, and the need for continuous technological upgrades. Companies like XLC address these challenges through ongoing investment in research, staff training, and quality assurance systems.

Conclusion: Shaping the Future of Play

Injection molding OEM is a driving force behind the modern toy industry, enabling brands to innovate, scale, and compete globally. Xilici Company (XLC) exemplifies the best of this sector, combining technical expertise, sustainable practices, and a client-focused approach. As the industry continues to evolve, the partnership between toy brands and injection molding factories like XLC will remain central to delivering safe, exciting, and high-quality toys to children around the world.

Whether you’re a toy startup or an established brand, working with an experienced injection molding OEM like XLC can unlock new possibilities and set your products apart in a crowded marketplace. The future of play is being shaped today, one molded toy at a time.